Product durability and reliability under temperature fluctuations are crucial; failing to test these can lead to costly malfunctions and product recalls. Temperature cycling chambers are the solution for dependable performance testing across extreme conditions.

A temperature cycling chamber is specialized test equipment used to expose products to rapid temperature changes, ensuring they can withstand varying environments without compromising functionality or safety.

To understand the full benefits and workings of a temperature cycling chamber, let’s explore its core features, applications, and advantages.

ARTICLE CONTENT

Article Introduction

Temperature cycling chambers are essential for industries that demand high reliability in their products, such as aerospace, automotive, electronics, and energy. Designed to simulate rapid changes from high to low temperatures, these chambers help manufacturers ensure that products perform consistently under different environmental conditions. By using temperature cycling chambers, companies can confidently bring robust, reliable products to the market while identifying and addressing potential vulnerabilities early in the development phase.

What is a Temperature Cycling Chamber?

A temperature cycling chamber, also known as a thermal cycling chamber, is an environmental test device engineered to expose products, materials, or components to controlled cycles of temperature extremes. By switching rapidly between high and low temperatures, the chamber evaluates a product’s ability to withstand thermal stress, ensuring durability and functionality when exposed to different operational environments. These chambers feature advanced temperature control systems that precisely manage heating and cooling rates and often include humidity settings to expand testing capabilities.

What Are Temperature Cycling Chambers For?

Temperature cycling chambers are utilized across multiple industries to validate product quality, safety, and durability. Here are key applications:

- Automotive and Aerospace:Parts are tested for resilience against rapid temperature changes encountered during flights, high-speed travel, and exposure to external elements.

- Electronics and Semiconductors:Critical for components sensitive to temperature shifts, ensuring long-term stability and functionality in consumer electronics and industrial equipment.

- Energy and Battery Testing:Battery packs and renewable energy components are validated for reliability and safety in diverse climate conditions.

- Medical Devices:Ensures that life-critical devices maintain performance standards even under severe thermal shifts, as might be encountered during transportation or usage in extreme climates.

The chamber thus plays a pivotal role in validating a product’s lifecycle, making it essential for industries with stringent safety and reliability standards.

What Are the Advantages of a Temperature Cycling Chamber?

Using temperature cycling chambers offers several benefits:

- Product Reliability:By subjecting products to accelerated life testing, manufacturers can predict long-term performance and identify potential issues before products reach consumers.

- Enhanced Quality Assurance:Allows for strict quality control by revealing flaws or weaknesses that may only manifest under repeated thermal stress.

- Energy Efficiency:Advanced models are energy-efficient, with precise control systems that minimize power consumption even during intense testing cycles.

- Adaptable Testing Conditions:Many chambers include customizable settings for humidity, vibration, and pressure, making them suitable for a range of test environments beyond temperature.

- Cost Savings:Early detection of product vulnerabilities reduces costs associated with recalls, repairs, or replacements, contributing to a lower total cost of ownership.

These advantages make temperature cycling chambers indispensable for manufacturers aiming to build durable, reliable, and high-quality products.

Temperature Cycling and Stability Testing

Temperature cycling and stability testing are essential to quality control processes. In temperature cycling, products undergo rapid shifts between high and low temperatures, simulating real-world thermal exposure over a short period. This process accelerates wear, allowing manufacturers to assess failure points, such as material fatigue or seal degradation. Stability testing, on the other hand, measures a product’s response to prolonged exposure at a stable temperature, often combined with controlled humidity levels.

Together, these tests provide a comprehensive assessment of how a product will behave in real-world conditions, from transportation and storage to actual usage in challenging climates. Testing with temperature cycling chambers also enhances the accuracy of life cycle assessments, leading to improvements in material selection, design, and manufacturing processes, and ultimately offering greater confidence in product reliability.

Summary

Temperature cycling chambers are crucial for ensuring product performance and safety in fluctuating environments.

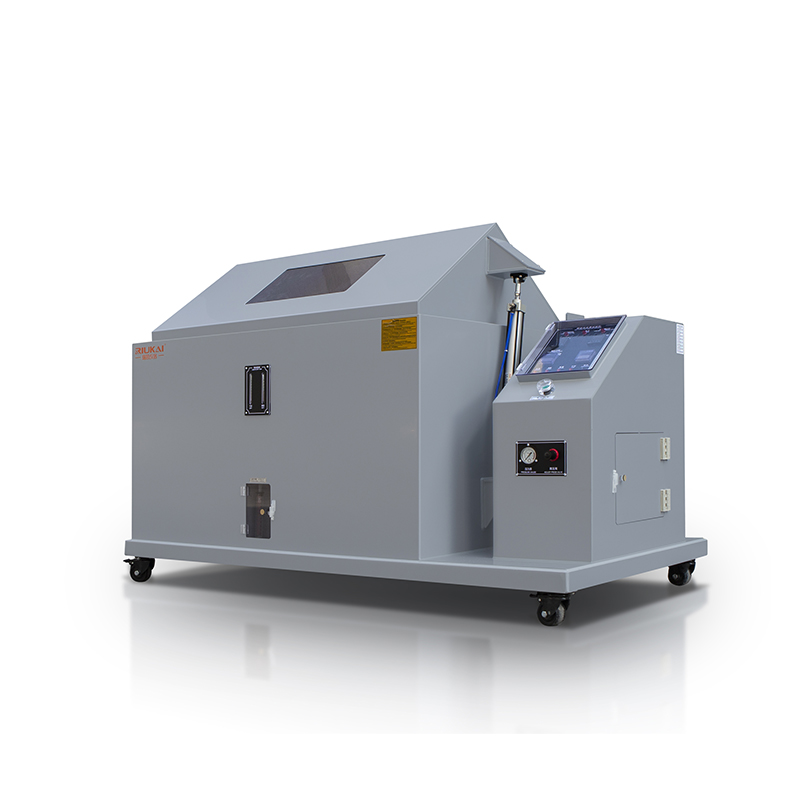

About RIUKAI Climatic Chamber

As a professional supplier of climatic chamber, RIUKAI provides climatic chamber including High and Low Temperature Test Chambers, Thermal Shock Test Chambers, Walk-in Test Chambers, Rapid Temperature Change Test Chambers, PCT Pressure Cooker Aging Test Chambers, Highly Accelerated Stress Test Chambers, etc.,which are widely used in electronics,automotive, aerospace, and other industries, to meet the testing needs of different customers !

RIUKAI are a professional 25+ years manufacturer in climatic chamber、environmental test chambers and so on.Our company has passed ISO 9001 quality management system, ISO 14001 quality management system and ISO 45001 quality management system. Welcome to consult for Catalog and Product. you can contact us at email export@riukai.com.