RIUKAI TECHNOLOGY has 25+ years of experience in the field of environmental testing equipment testing to meet the needs of our customers.

Altitude Chamber/Hypobaric Test Chamber

Altitude Chamber/Hypobaric Test Chamber

Product Model:R-PTD Series

Main Parameters:

- Pressure range: RP~ 0.5Kpa

- Temperature range: 0℃/-20℃/-40℃/-70℃ ~ +150

- Temperature fluctuation: +/- 0.5℃(normal pressure)

- Temperature uniformity: +/- 2℃(normal pressure)

Description of Altitude Test Chamber / Hypobaric Test Chamber:

Altitude Chamber / Hypobaric Chamber is suitable for products (machine), parts and materials for high temperature, low temperature, altitude (not higher than 30,000 metres above sea level or 45,000 metres), as well as high and low temperature cycling test and temperature – altitude integrated test, high and low temperature test chamber can be used for heat dissipation test samples and non-heat dissipation test samples test.

For the test of heat dissipation test samples, the power of heat dissipation should not exceed the cooling capacity of the test chamber, because the cooling capacity is a dynamic value, which changes with the change of temperature point.

Features of Altitude Test Chamber / Hypobaric Test Chamber:

- It accelerates the aging process and brings accurate experimental results.

- Multiple safety protection devices.

- The test chamber and steam generator are independent of each other, reducing mutual interference and completely avoiding condensation.

- The inner box is made of high alloy, special corrosion-resistant 316# stainless steel with mirror polishing treatment, which is carefully designed and manufactured.

- The box adopts circular arc design,no solder joint process, in line with industrial safety standards.

- Remote centralized monitoring with RS485/RS-232.

- Wide range of humidity options. Saturated type: 100%, unsaturated type: 65% or other.

- A integrated silic gel door gasket, air tightness is very good, and long operation life.

| Model | R-PTD-150 | R-PTD-562 | R-PTD-1000 | |

| Inner tank volume | 150L | 562L | 1000L | |

| Inner chamber size (W * H * D) mm | 500*500*500 | 750*750*1000 | 1000*1000*1000 | |

| Outer chamber size (W * H * D) mm | 700*1400*1300 | 1050*1780*1970 | 1400*2000*3250 | |

| Performance parameter | Pressure range | Atmospheric pressure ~ 1kPa (or atmospheric pressure ~ 0.5kpa) | ||

| Pressure accuracy | ≤± 2KPa (at atmospheric pressure ~ 40kpa);± 5% (40kpa ~ 4kPa);± 0.1kpa (4kPa ~ 1kPa) | |||

| Depressurization rate | ≤ 45min (atmospheric pressure → + 1kPa) | |||

| Boost and depressurization time | Less than 10min (no load, normal temperature and pressure, drying in the box) | |||

| Temperature range | -70~+150℃ | |||

| Temperature fluctuation | ± 0.5 ℃ (under normal pressure and no load) | |||

| Temperature uniformity | ≤ 2.0 ℃ (under normal pressure and no-load) | |||

| Temperature deviation | ± 2.0 ℃ (under normal pressure and no load) | |||

| Heating time | Average 3 ℃ / min in the whole process (under normal pressure and no-load) | |||

| Cooling time | Average 1 ℃ / min in the whole process (under normal pressure and no-load) | |||

| Structure | Shell | Plastic spraying on the surface of cold rolled steel plate | ||

| Inner liner | SUS304 stainless steel with high temperature and corrosion resistance + stainless steel square grid welding | |||

| Refrigeration | Refrigeration mode | water-cooling | ||

| Refrigerator | Imported compressor | |||

| Viewing window (mm) | two hundred×300mm wide×High) | |||

| Temperature sensor | Armored platinum resistance | |||

| Pressure sensor | Silicon resistance pressure transmitter | |||

| Controller | Siemens PLC module (including embedded PLC control software of Ruikai instrument) + 7-inch color LCD touch control screen | |||

| Installed power | 18KVA | 19.2KVA | 32.5KVA | |

| Power Supply | AC380V 50Hz three-phase four wire system + grounding wire | |||

| Standard configuration | 1 product instruction, 1 test report, 1 Certificate and quality assurance certificate, 2 shelves and 4 shelving strips. | |||

| Meet the standard | GB / t2423.21 low air pressure test method, cjb150.2 air pressure (height) test method, cjb 150.3 high temperature test, gjb150.6 air pressure temperature test method, gb10590 technical conditions of low air pressure test chamber. | |||

| Note: it can be customized according to customer requirements. | ||||

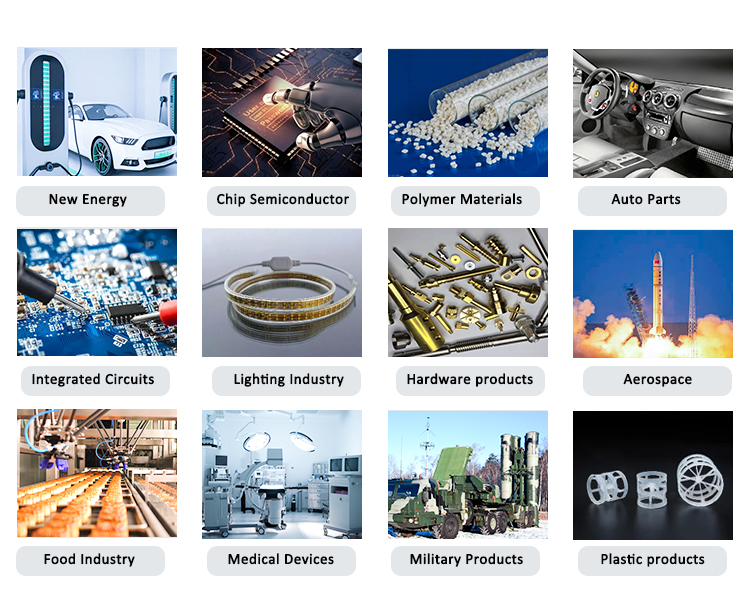

Category

ANYTHING YOU COULDN’T FIND?

Talk with our sales

Riukai is a set of simulated natural environment reliability test equipment design, research anddevelopment, production and sales and service of national high-tech enterprises, research institutes tocooperate in the production and research units, the domestic reliability of environmental testing equipmentindustry pioneer enterprises.

- OEM.

- No MOQ.

- One-year quality assurance.

- Unbeatable prices.

- Comprehensive brochure you can download.

- Fast Respond Or enthusiasm.

- Fast delivery.

- Excellent R&D and innovation capability.

SEND US AN EMAIL

Contact Us

Talk to our sales staff to understand your needs.