- RIUKAI TECHNOLOGY has 25+ years of experience in the field of environmental testing equipment testing to meet the needs of our customers.

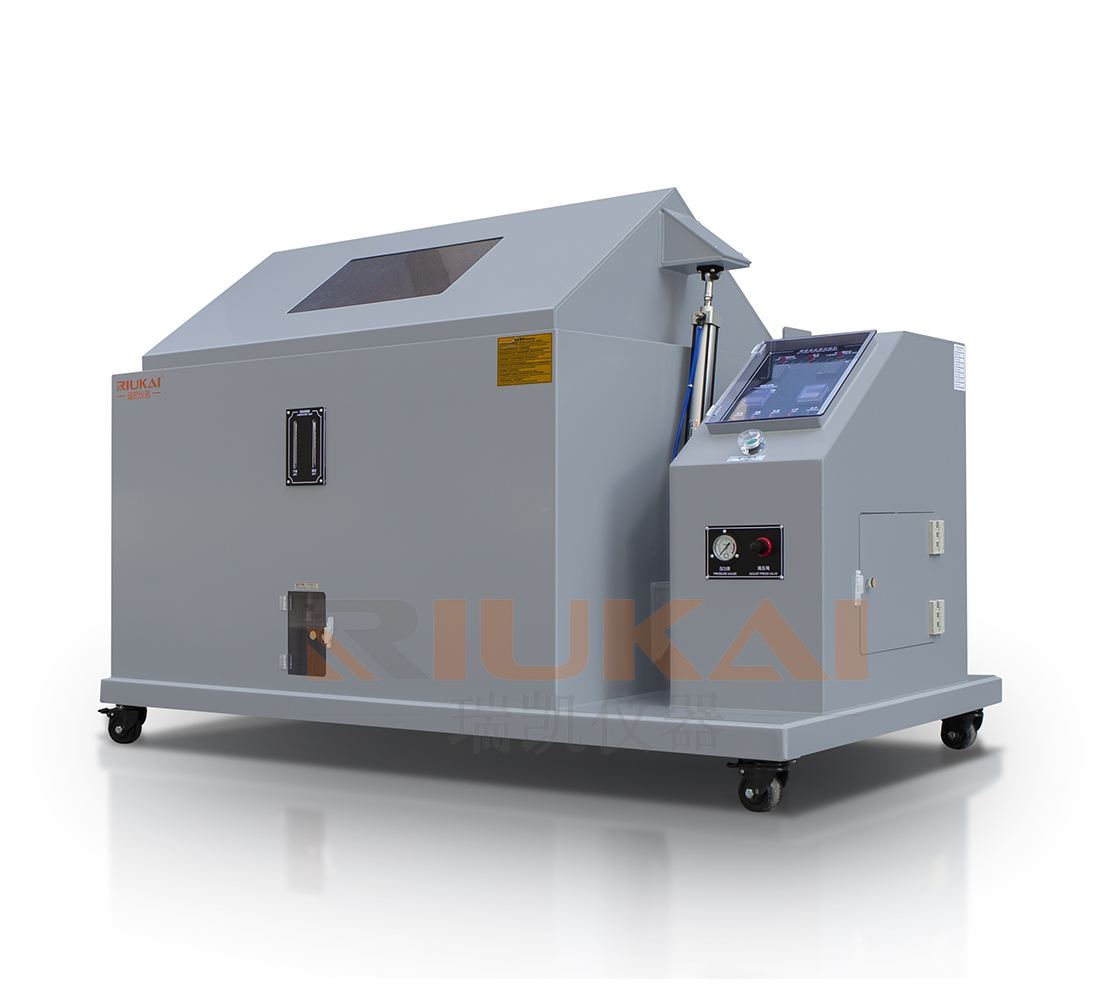

Salt Spray Test Chamber

Salt Spray Test Chamber

Product Model: R-YW-volume Series

Main Parameters:

- Conforms to ASTM B-117, B-287, JIS D0205, H-8681, Z-2771, K-5400 and other standards.

- Push-button or programmable touch screen controller

- Customised walk-in larger salt spray test chambers available

Applications of Salt Spray Test Chambers :

Salt Spray Test Chambers are commonly used in various industries, including automotive, aerospace, marine, electronics, and construction, where materials and coatings are susceptible to corrosion due to exposure to saltwater, humidity, and aggressive environmental conditions.

What is Salt Spray Test Chamber?

How does a Salt Spray Test Chamber work?

The Salt Spray Test Chamber creates an environment where a saltwater mist, usually composed of a 5% sodium chloride (NaCl) solution, is continuously sprayed onto the test samples. The chamber’s temperature and humidity are controlled to maintain specific testing conditions, ensuring reproducibility and consistency.

The test samples are carefully prepared and placed inside the chamber, and the duration of the test can vary depending on the intended application and industry standards. The samples are then exposed to the corrosive salt spray, and the chamber’s environment is monitored throughout the testing period.

During and after the test, the samples’ appearance and performance are observed and analyzed to evaluate any signs of corrosion, such as rust, blistering, or color changes. Test results allow researchers and manufacturers to determine the materials’ corrosion resistance, assess the effectiveness of protective coatings, and make informed decisions about product quality and design improvements.

| Model | R-YW-60 | R-YW-90 | R-YW-120 | R-YW-160 | R-YW-200 | ||

| Inner dimension WxHxD(mm) | 600x400x450 | 900x500x600 | 1200x600x800 | 1600x600x1000 | 2000x600x1000 | ||

| Exterior dimension WxHxD(mm) | 1050x1000x680 | 1410x1110x810 | 2080x1300x1050 | 2430x1400x1250 | 2830x1450x1250 | ||

| Installed power | 1.5(kw) | 2.5(kw) | 3.5(kw) | 4.5(kw) | 4.5(kw) | ||

| Brine tank capacity | 15L | 25L | 40L | 40L | 40L | ||

| Number of collectors | 1 | 2 | 2 | 2 | 2 | ||

| Number of spray towers | 1 group | 1 group | 2 groups | 2 groups | 2 groups | ||

| Temperature range | RT+10℃~60℃ | ||||||

| Humidity range | ≥85% R.H or more (dry and wet bulb comparison table calculation) | ||||||

| Temp.uniformity | ≤±1℃ | ||||||

| Temp.fluctuation | ≤±0.5℃ | ||||||

| Pressure barrel temperature | RT+10℃~80℃ | ||||||

| Salt Mist Settling Volume | 1~2ml/h.80cm² (collected for at least 16 hours, average value taken) | ||||||

| Spray pressure | 1.00±0.01kgf/cm² | ||||||

| PH value (PH) | PH=6.5~7.2(NSS)/PH=3.0~3.3(ACSS、CASS) | ||||||

| Test time | 1~999(S、M、H)(Adjustable) | ||||||

| Saline solution concentration | Sodium chloride solution concentration 5% (neutral salt spray) | ||||||

| Sodium chloride solution 5%+ glacial acetic acid (acetate spray) | |||||||

| Sodium chloride solution concentration 5% + glacial acetic acid + 0.26g CuCl2/L (copper accelerated salt spray) | |||||||

| Spray way | Continuous spraying + intermittent spraying | ||||||

| Heating methods | Direct steam heating method | ||||||

| Controller | Push button digital display controller | ||||||

| Standard configuration | 1 round bar, 1 V-shaped sample holder, 2 nozzles, 2 sets of funnels and 2 sets of measuring cylinders | ||||||

| Safety protection device | Over temperature protection | ||||||

| Lack of water protection | |||||||

| Over current protection | |||||||

| Power supply | AC 220V/50HZ | ||||||

Category

ANYTHING YOU COULDN’T FIND?

Talk with our sales

Riukai is a set of simulated natural environment reliability test equipment design, research anddevelopment, production and sales and service of national high-tech enterprises, research institutes tocooperate in the production and research units, the domestic reliability of environmental testing equipmentindustry pioneer enterprises.

- OEM.

- No MOQ.

- One-year quality assurance.

- Unbeatable prices.

- Comprehensive brochure you can download.

- Fast Respond Or enthusiasm.

- Fast delivery.

- Excellent R&D and innovation capability.

SEND US AN EMAIL

Contact Us

Talk to our sales staff to understand your needs.