- RIUKAI TECHNOLOGY has 25 years of experience in the field of environmental testing equipment testing to meet the needs of our customers.

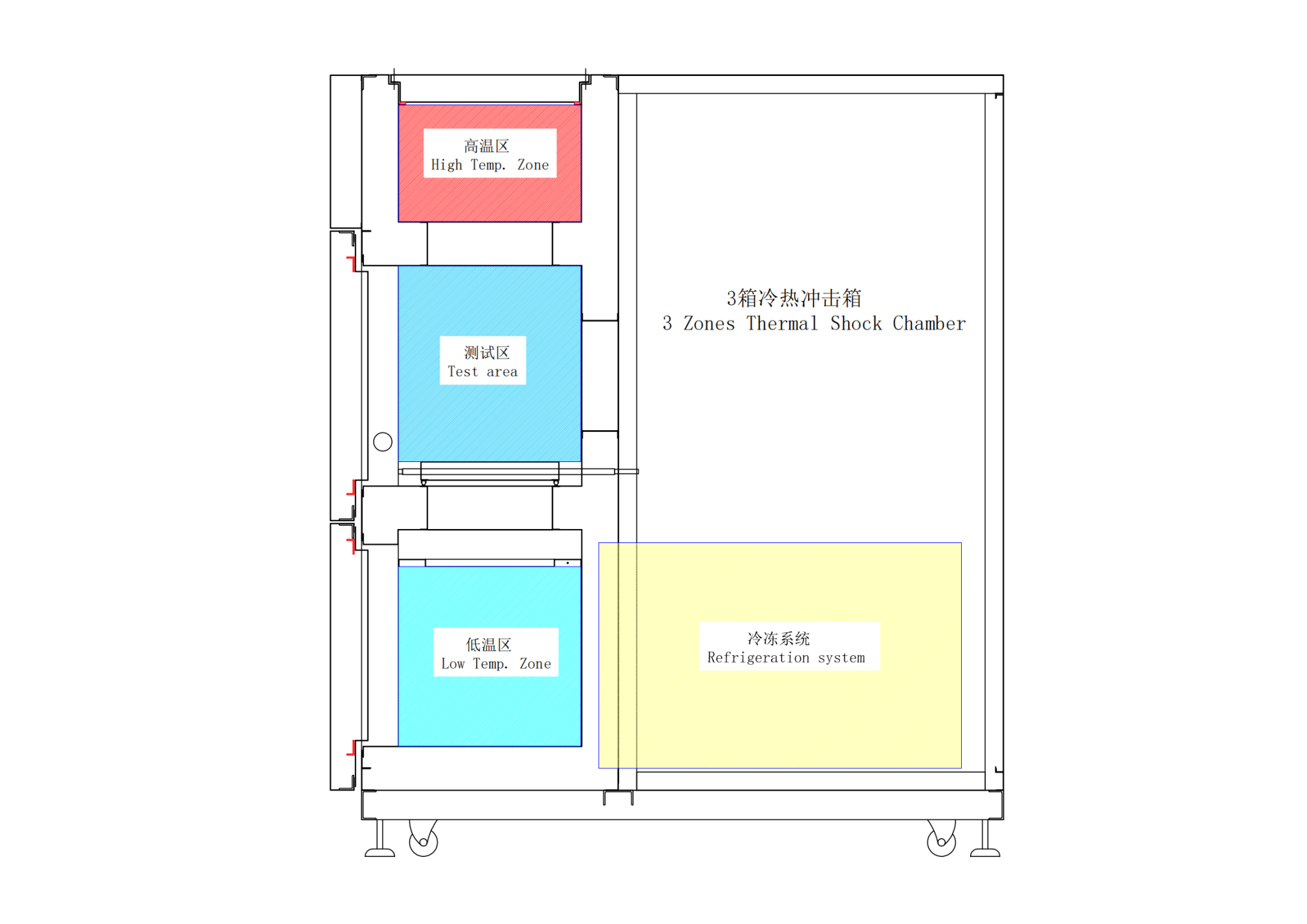

3 Zones Type Thermal Shock Chambers

3 Zones Type Thermal Shock Chambers

Product Model: RK-TS3 Series,50L~300L

Main Parameters:

- Temperature shock range:-40℃/-55℃/-60℃ ~+180℃

- Temperature recovery time: ≤ 5 min(Customizable))

- Basket move time: within 10 seconds

- Customizable viewable windows

Description of 3 Zones Type Thermal Shock Chambers:

The 3-zone thermal shock test chamber is used to test the degree of load-bearing of products in instantaneous continuous high and very low-temperature environments and to test the chemical changes or physical damage caused by them in the shortest possible time.It is the ideal test equipment for testing electronic components, metals, chemical materials, the aerospace industry, BGA, PCB boards, IC, semi-conductive ceramics, etc.

Features of 3 Zones Type Thermal Shock Chambers:

- Three zones: high temp. zone, test zone,and low temp. zone, in the room temp. the state can be operated to test products.

- Horizontal airflow design assures uniform results

- Adopt a binary cooling system,with a quick cooling effect,the cooling method is water or air-cooled.

- Excellent cooling capacity, and the impact exposure time in both high and low temp. zones can reach 15 min.

- Defrosting round can reach more than 200 cycles,which can ensure the accuracy of the experiment.

- With USB and RS-232 C communication ports, it can be connected to a PC for control.

Test Standard of 3 Zones Type Thermal Shock Chambers::

● IPC TM-650 2.6.6-1987 Printed Circuit Board Temperature Cycling

● Bellcore-Bell Communications Laboratories

● GJB 150.5-86-Environmental testing of military equipment Temperature shock test

● GR-1221-CORE-Bellcore Communications Laboratories

● JIS C0025-1988-Temperature Change Test for Electrical and Electronic Appliances

● MIL-STD-202F-Three-Case Gas Temperature Shock Test for Electronic and Electrical Components

● MIL-STD-883E-Reliability Test AFSL Temperature Cycle Tests

● IEC 68-2-14 Basic Environment Part 2: Section 14: Test N: Temperature Change

| Model | RK-TS3-50 | RK-TS3-100 | RK-TS3-150 | RK-TS3-200 | RK-TS3-300 | |||

| Inner dimension WxHxD(mm) | 350×400×350 | 500×450×450 | 500×600×500 | 650×460×670 | 800×460×815 | |||

| Exterior dimension WxHxD(mm) | 1250×1850×1300 | 1400×2000×1400 | 1400×2000×1450 | 1550×1900×1740 | 1700×1900×2100 | |||

| Preheating temperature | 60℃~200℃ | |||||||

| Heating time | Room temperature → + 200 ℃ ≤ 30 min | |||||||

| Pre-cooling temperature lower limit | -80℃ | |||||||

| Cooling time | Room temperature → – 80 ℃ ≤ 75 min | |||||||

| High temperature impact range | +60℃~+150℃ ( Customized to 180℃, 200℃) | |||||||

| Low temperature shock range | L:-10℃~-40℃ F:-10℃~-55℃ X:-10℃~-65℃ |

|||||||

| Temp. fluctuation | ≤±0.5℃ | |||||||

| The temperature deviation | ≤±2℃ | |||||||

| Temperature recovery time | ≤5 min | |||||||

| Switching time | Within 3 seconds | |||||||

| Exterior material | Cold rolled plate + Powder coating | |||||||

| Interior material | SUS#304 Stainless Steel | |||||||

| Insulation material | Rigid Polyuethane Foam and Glass Fiber Wool | |||||||

| Refrigeration system | Air(Water)cooling condenser | |||||||

| Fully hermetic worm-rotor type freezers or semi-hermetic screw-type compressors | ||||||||

| Noise | ≤65 dba or ≤75 dba | |||||||

| Controller | Touch screen controller / Supports multiple languages / Programmable systems | |||||||

| Data storage and functional interface | USB data interface: USB storage interface, | |||||||

| TCP/IP communication interface: RJ45 data interface | ||||||||

| Power supply | AC3 380V 50Hz | |||||||

Category

ANYTHING YOU COULDN’T FIND?

Talk with our sales

Riukai is a set of simulated natural environment reliability test equipment design, research anddevelopment, production and sales and service of national high-tech enterprises, research institutes tocooperate in the production and research units, the domestic reliability of environmental testing equipmentindustry pioneer enterprises.

- OEM.

- No MOQ.

- One-year quality assurance.

- Unbeatable prices.

- Comprehensive brochure you can download.

- Fast Respond Or enthusiasm.

- Fast delivery.

- Excellent R&D and innovation capability.

SEND US AN EMAIL

Contact Us

Talk to our sales staff to understand your needs.