Different temperatures inside the environmental test chamber:

When we first hear that someone is looking for a test chamber, they are sometimes surprised to learn that we can drop the temperature to -94 ℉ (-70 ℃).

- 20℃ above room temperature:Test chambers without a refrigeration system are usually not able to guarantee a stable temperature close to the ambient temperature because of the heat generated by the fan circulating the air. A refrigeration system is required even if only a stabilised ambient temperature is needed. Such low temperatures are usually used for ovens.

- 5℃ to -20℃:This is the lowest temperature that can be achieved with a standard refrigeration system using R-134a refrigerant. This refrigerant is also used in new air-conditioning systems and refrigerators. Due to its limited refrigeration range, it is not commonly used in the test chamber industry.

- -35℃ to -40℃:Test chambers using R-404A or R-507 refrigerant can reach this temperature range. These systems are called ‘single stage’ refrigeration systems, meaning that there is only one compressor. These chambers are usually only used up to -20°C or -25°C when tested for temperature cycling.

- -65℃ to -73℃:Test chambers can reach temperatures this low using ‘cascade’ refrigeration systems. These low temperatures can be achieved by using a ‘high stage’ refrigeration circuit to cool a “low stage”circuit.

Refrigeration systems for environmental test chambers:

The design of the refrigeration system and the method of control are critical to achieving these low temperatures. For example, by using advanced multi-stage compression refrigeration technology and compound refrigeration systems, it is possible to significantly reduce energy consumption while providing the same amount of cooling capacity.

At the same time, the application of cold storage technology, intelligent control systems, highly efficient insulation materials and waste heat recovery technologies have also had a significant impact on the energy efficiency and development trends of environmental test chambers.However, there are some limitations in reaching low temperatures in environmental test chambers. For example, the choice of refrigerant, the design of the refrigeration system, the insulation properties of the chamber, and the organisation of the airflow inside the test chamber all affect its ability to reach and maintain low temperatures.

In addition, the size and shape of the test chamber can affect its performance, as larger test chambers require more energy to cool and may have difficulty achieving uniform temperature distribution inside. The efficiency and reliability of the cooling system is also a limiting factor, as more complex systems may be more difficult to maintain and may have more points of failure.The low temperature performance of an environmental test chamber relies on the design of its refrigeration system. Test chambers manufactured by RIUKAI use highly efficient refrigeration technologies, such as multi-stage cascade systems, to achieve temperatures of -70°C or even lower to meet stringent testing standards.

RIUKAI’s design takes into account the impact of chamber size and shape on temperature uniformity and system reliability, ensuring high performance and durability of the equipment. Choose RIUKAI’s test chambers and rely on their superior performance in low-temperature testing.

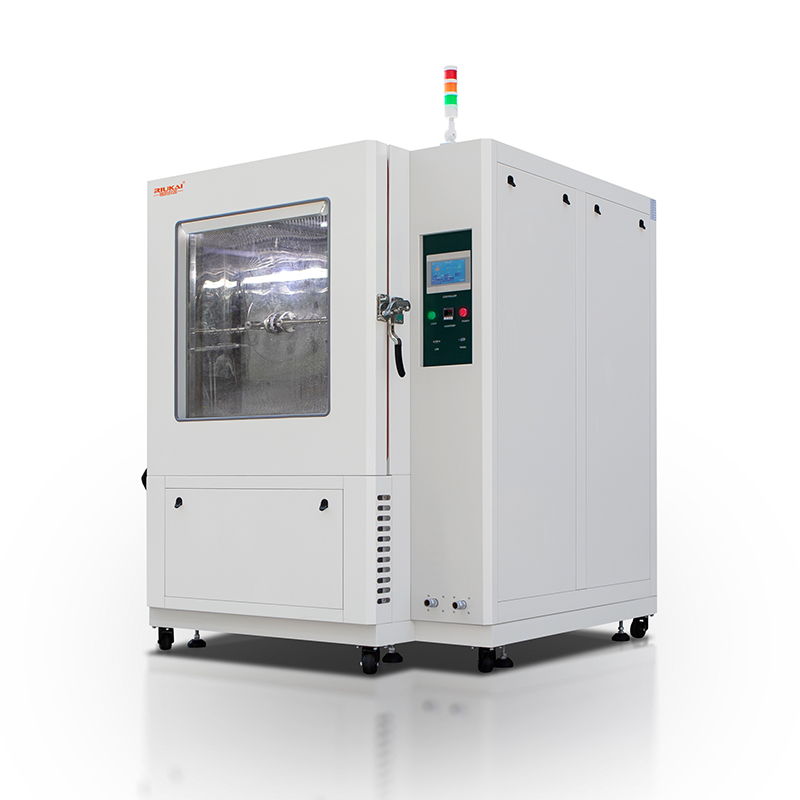

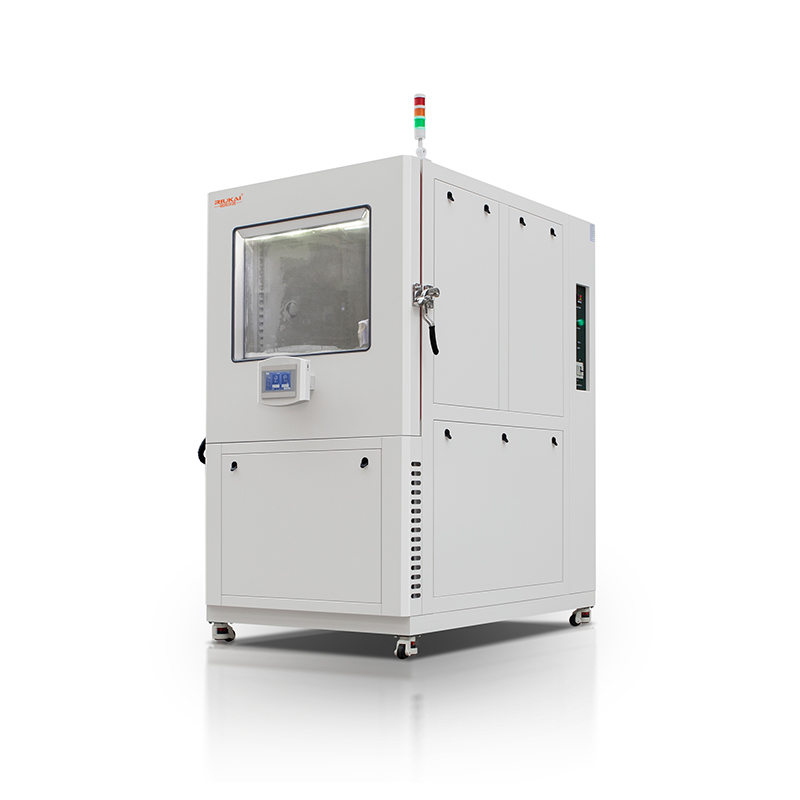

What is the RIUKAI brand of environmental test chambers?

RIUKAI ‘ products include temperature and humidity test chamber, high and low temperature test chamber, thermal shock test chamber, environmental test chambers,etc., which are widely used in electronics, automotive, aerospace, battery, food, construction, energy, pharmaceutical and other industries.RIUKAI’ environmental test chambers also have the following features:

- Programming control: 7-inch wide colour LCD programmable control system.

- Remote monitoring: LAN to monitor equipment operating status, change programme settings, start/stop operation;

- High performance: extreme test range up to 95 ℃, relative humidity 98%;

- Customised production: customised specifications, cooling methods, water supply and language options are available on request.

RIUKAI’ environmental test chambers are ideal for ensuring product quality and performance in extreme low temperature conditions.

1-1.jpg)