What Is The Purpose Of The Thermal Shock Chamber?

What Is A Thermal Shock Chamber Used For?

Thermal Shock Test – Temperature Cycling

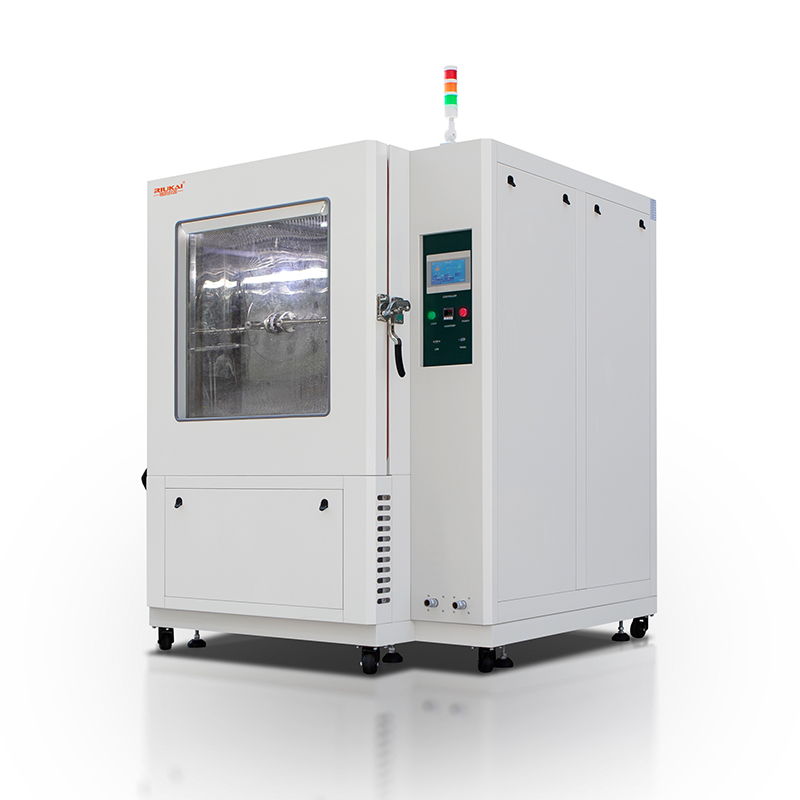

In the complex landscape of industrial processes, Thermal Shock Chamber, also known as temperature test chambers, stand as essential tools serving a variety of functions. Their usage spans multiple industries and applications, showcasing versatility beyond conventional testing norms.Demonstrating their capabilities in steady-state or stability testing, these chambers create an environment of equilibrium for products to undergo thorough scrutiny, ensuring they endure consistent conditions.

Thermal Cycling Exploration:For thermal shock chambers,engaging in thermal cycling or thermal shock processes, these chambers subject specimens to fluctuating temperatures, simulating real-world scenarios where products must withstand unpredictable thermal variations.

Why Choose RIUKAI Thermal Shock Chamber ?

As industries and applications intertwine with the intricate dance of thermal testing, these chambers emerge not just as apparatus but as custodians of quality, reliability, and endurance. Their silent vigilance ensures that products, born from the crucible of innovation, stand resilient against the unforgiving touch of temperature.

Professional Guidance in Thermal Shock Testing (thermal shock chamber) with RIUKAI.Navigating the intricate landscape of thermal shock testing demands not just equipment but seasoned expertise. At RIUKAI, we bring forth a wealth of experience, having mastered the art of thermal shock testing over many years. Our commitment goes beyond providing testing chambers; we stand as your partners in ensuring the success of your tests.

Personalized Support:Our team of thermal shock testing (thermal shock chamber) experts is dedicated to providing personalized support tailored to your unique challenges. We understand that each testing scenario is distinct, and our experts are ready to collaborate with you to ensure that your thermal shock tests(thermal shock chamber) are not just conducted but conducted with precision and relevance.

RIUKAI has 25 years of source factory experience, mature experience in manufacturing large-scale non-standard complex test equipment and installation capacity, and has rich experience and technology accumulation in producing and manufacturing thermal shock test chambers.

Thermal Shock Chambers For The Industry:

Electronics Validation:For thermal shock chambers,validating the electronic ecosystem, these chambers ensure the resilience of electronic components against thermal challenges, vital in the face of technological progress.

Automotive Scrutiny:For thermal shock chambers,playing a pivotal role in the automotive industry, these chambers scrutinize components destined for vehicles, from engine parts to electronic systems, ensuring durability on the road.

Aerospace Reliability:For thermal shock chambers,In the aerospace sector, these chambers become indispensable for testing components bound for the sky, ensuring the reliability of aerospace equipment in extreme conditions.

Innovation Verification:Industries driven by innovation embrace these chambers as vital tools.As breakthroughs propel industries forward, thermal shock test becomes a cornerstone, validating the resilience and functionality of cutting-edge products.

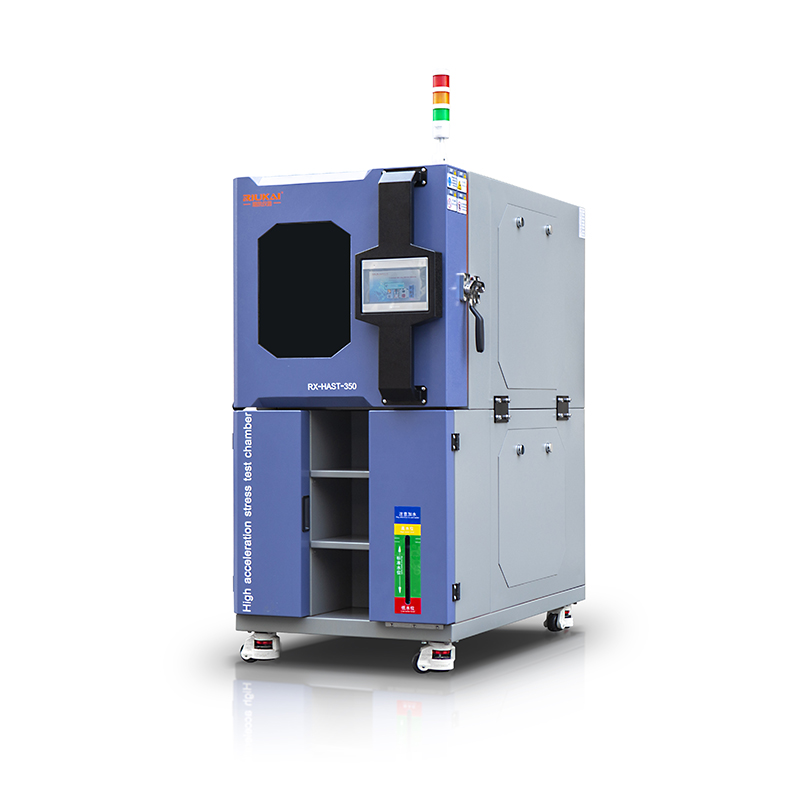

Comprehensive Solutions For Cold And Thermal Shock Chamber :

RIUKAI goes beyond being a provider of testing chambers; we are your partners in success. From suggesting suitable test conditions to guiding you on the right specifications, we offer end-to-end solutions that align with your goals. Trust in our expertise to navigate the complexities of thermal shock testing seamlessly.When it comes to thermal shock testing, RIUKAI isn’t just a supplier-we are your allies in achieving testing excellence.RIUKAI will help you to select one of two or three zone thermal shock test chambers, which have been developed in accordance with the customer’s testing requirements and offer the highest levels of performance, efficiency, productivity, reliability and safety.

1-1.jpg)