What is an industrial oven?

An industrial oven is a piece of heating equipment that fulfils the requirements of a specific process for precise temperature control and temperature uniformity. It is commonly used in production environments where materials need to be heated. Depending on the application, industrial ovens vary in size and volume, as well as in the maximum temperature they can reach. Industrial ovens are manufactured in accordance with industry standards such as NADCAP AMS2750G and CQI-9.

What is the difference between a laboratory oven and an industrial oven?

In principle, the difference between laboratory ovens and industrial ovens is size. Industrial ovens tend to work with larger batches of material, whereas laboratory ovens are usually used to work with smaller samples. Industrial ovens are more robustly constructed to meet the requirements of production facilities.

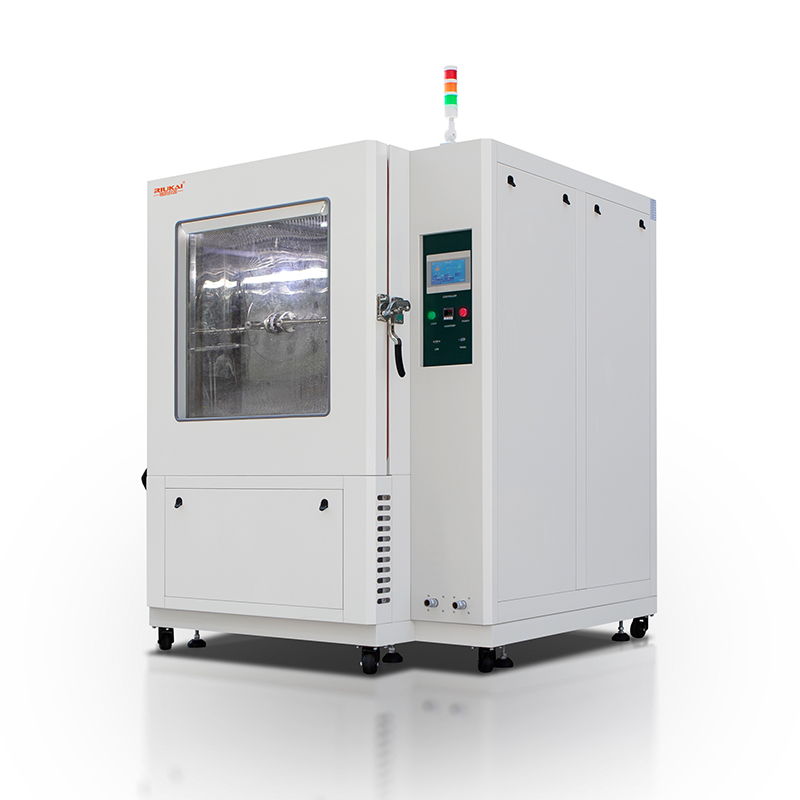

Custom Oven Reference Models

.jpg)

.jpg)

How do industrial ovens work?

Industrial ovens work by heating the air inside the chamber using motorised heating elements. The air is usually mixed by means of a circulating fan fitted in the heating chamber to ensure that the heat is evenly distributed, this is often referred to as ‘forced convection’. Components placed inside the oven chamber are heated by the hot air.

What is the temperature range of industrial ovens?

The typical operating temperature of an industrial oven depends entirely on the requirements of the application.RIUKAI offers ovens up to 400 ℃ for applications such as drying and dehumidification.

How much does it cost to run an industrial oven?

The running cost of an industrial oven depends largely on the operating temperature and the size of the chamber. Energy efficient industrial ovens are well insulated and the power consumption is easy to calculate. Running costs are higher if the process requires a lot of air exchange, for example to remove potentially explosive solvents.

1-1.jpg)