What is an Aging Test Chamber?

Are you struggling to ensure the durability of your products? Poor testing methods can lead to costly failures and unhappy customers. The solution lies in investing in an aging test chamber, which ensures your products withstand the test of time.

Top 10 Aging Test Chamber Manufacturers:

RUIKAI is one of the top 10 aging test chamber manufacturers in the world and has been in reliability aging test chamber for 25+ years.Discover leading manufacturers that provide reliable aging test chamber, helping you maintain product quality and compliance. These trusted brands offer advanced technology for accurate testing results.Understanding aging test chamber is essential for product reliability. Read on to explore their manufacturing processes, functionality, principles, and maintenance.

Aging Test Chamber Manufacturing Process

The manufacturing process of an aging test chamber involves several critical steps to ensure quality and precision.

First, the design phase incorporates customer requirements and industry standards.

Next, high-quality materials are selected for durability and performance.

Skilled technicians then assemble the components, integrating advanced technologies such as temperature and humidity controls.

After assembly, rigorous testing is conducted to validate the chamber’s functionality and accuracy. Quality assurance checks are performed at every stage, ensuring the final product meets specifications. This meticulous process guarantees that Aging Test Chambers provide reliable and consistent performance for various applications.

How the Aging Test Chamber Works?

An aging test chamber simulates environmental conditions to accelerate the aging process of materials and products. It utilizes controlled temperature, humidity, and light exposure to create an accelerated aging environment. Products are placed inside the chamber, where these factors are meticulously regulated to mimic long-term exposure to real-world conditions. By doing so, manufacturers can observe how their products will perform over time, identify potential failures, and improve design before market release. This process not only enhances product quality but also reduces the risk of costly recalls and customer dissatisfaction.

What is the Principle of Aging Test Chamber?

The principle behind an aging test chamber is to replicate environmental stressors that products might face over their lifecycle. This chamber utilizes advanced technologies to control various factors, such as temperature fluctuations, humidity levels, and UV exposure. The aim is to accelerate the natural aging process, allowing manufacturers to evaluate product longevity and durability more quickly. By observing how materials respond to these simulated conditions, manufacturers can gain valuable insights into potential weaknesses and enhance their product designs accordingly. This proactive approach ultimately leads to improved product reliability and customer satisfaction.

What is the Preventive Maintenance of Aging Test Chamber?

Preventive maintenance is crucial for ensuring the longevity and reliability of an aging test chamber. Regularly scheduled maintenance checks can prevent costly downtime and extend the chamber’s lifespan. Key maintenance tasks include cleaning the interior and exterior, inspecting seals and insulation, calibrating temperature and humidity controls, and checking electrical components for wear. Additionally, it’s important to replace any worn-out parts promptly. By adhering to a preventive maintenance schedule, you can ensure that your Aging Test Chamber operates efficiently and continues to provide accurate testing results. This practice not only protects your investment but also ensures that your products meet high-quality standards.In summary, an aging test chamber is essential for assessing product durability and performance. Investing in one can significantly enhance your product’s reliability.

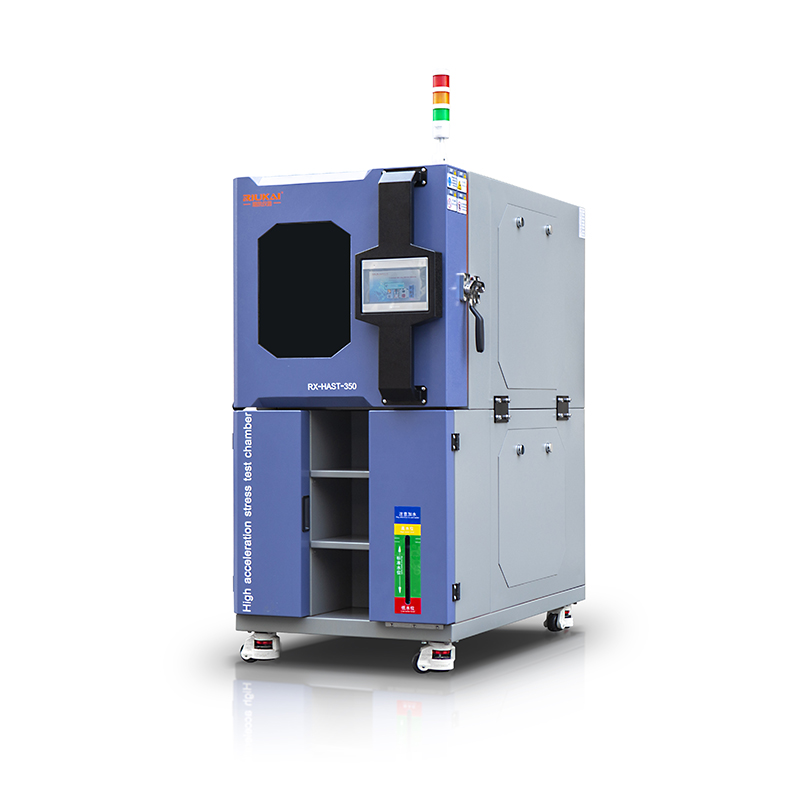

About RIUKAI Aging Test Chamber

As a professional supplier of climatic chamber, RIUKAI provides climatic chamber including high and low temperature test chambers, thermal shock test chambers, walk-in test chambers, rapid temperature change test chambers, PCT Pressure Cooker Aging Test Chambers, Highly Accelerated Stress Test Chambers, etc.,which are widely used in electronics,automotive, aerospace, and other industries, to meet the testing needs of different customers !

RIUKAI are a professional 25+ years manufacturer in climatic chamber、environmental test chambers and so on.Our company has passed ISO 9001 quality management system, ISO 14001 quality management system and ISO 45001 quality management system. Welcome to consult for Catalog and Product. you can contact us at email export@riukai.com. Click to learn more about the production details of RIUKAI test chambers.

1-1.jpg)