What is a thermal shock chamber?

RIUKAI’s Thermal Shock Chambers can be used to test the ability of most products to withstand drastic temperature changes. Simply put, a thermal shock tester can instantly subject a product to the most extreme temperature conditions. The purpose of using RIUKAI’s Thermal Shock Chamber for testing products under such conditions is to observe the change in product characteristics. To check whether different materials and coefficients of thermal expansion can lead to failure.

Thermal shock chambers serve a variety of industries and applications:

Electronics Validation/Automotive Scrutiny/Aerospace Reliability/Innovation Verification

How to choose RIUKAI Thermal Shock Chamber ?

Select a Thermal Shock Chamber with the following information:

- Temperature range

- Temperature exchange rate

- Volume (product dimensions and test chamber)

- Sample weight

- Performance of the sample to be tested

1.Temperature range

The specifications tables of the thermal shock cabinets define the minimum (min) and maximum (max) temperatures achieved. Almost all climatic chamber manufacturers set the maximum temperature at + 150 ° ~ + 180 ° C, although if required this can be extended to + 200 ° C as a option. Although the maximum temperatures are almost always the same, the minimum temperatures of the chambers using a mechanical cooling system allow them to be divided into two broad categories:

✓ Single cooling system -20 ° ~ -40 ° C

✓ Dual cooling system -50 ° ~ -70 ° C

The dual refrigeration system consists of two refrigeration systems, consisting of two separate compressor units arranged in series so that very low temperatures can be reached.Sometimes a thermal shock cabinet with a chosen dual refrigeration system does not need to reach an exceptionally low temperature below the desired cooling level, but to have a rapid cooling rate at a low temperature.

2. Temperature exchange rate

The rate of increase or decrease in the temperature inside the test chamber is called the temperature exchange rate (expressed in Kelvins or degrees Celsius per minute) and can vary greatly from model to model. , from 6 ° C / min to 10 ° C / min.The rate of temperature exchange obviously depends on the cooling capacity of the compressor and the heating of the heating rod installed in the chamber. In other words, the stronger the compressor, the faster the cooling rate and the more heat bars are installed in the chamber, the faster the heating rate.The temperature exchange rates given in the thermal shock test cabinet specifications table generally refer to the equipment performance with the test cabinet being empty (i.e. without a test piece).

3.Volume (product dimensions and test chamber)

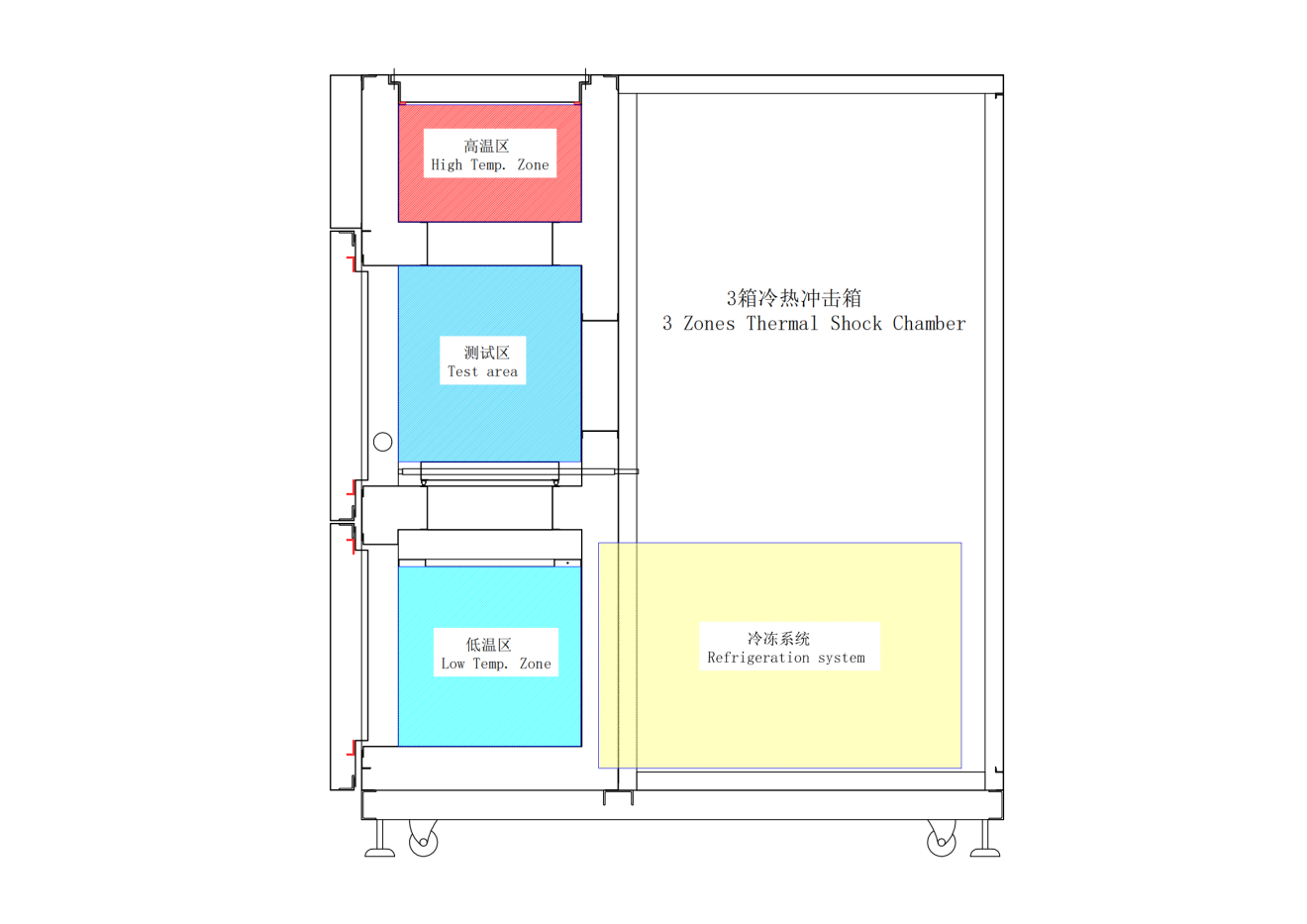

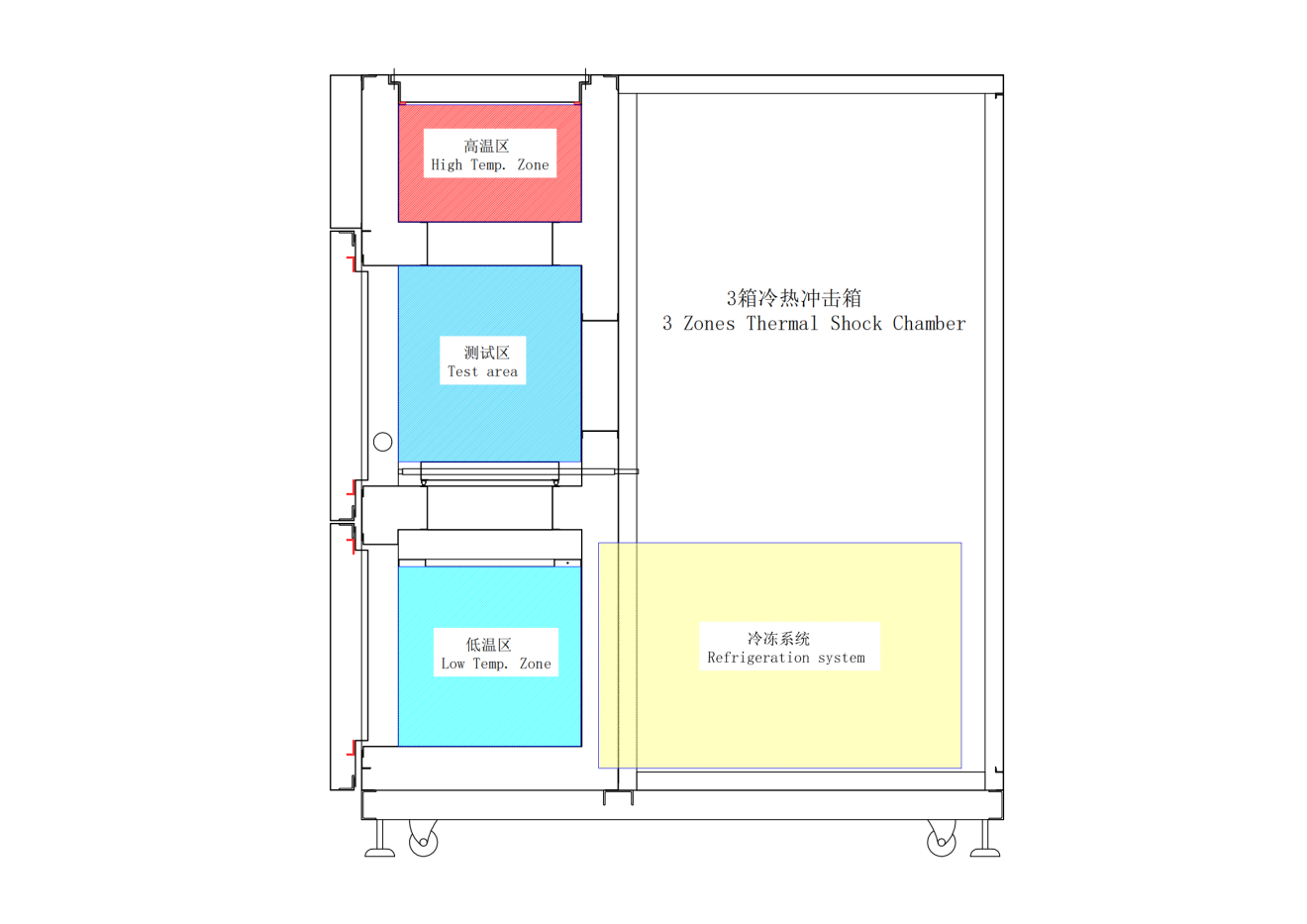

The main information to consider regarding the product to be tested is: product size, product material, product shape and weight of product under test.The size of the product allows you to determine the volume of the test cabinet, which is large enough to accommodate comfortably. It is generally best practice that the size of the test piece should not exceed one-third of the volume of the test chamber, although special consideration should be given to the shape of the product under test. In all cases the air shall be able to circulate freely to ensure that the variation and uniformity of temperature are almost equal (within the tolerance specified by the test) over the entire surface. of the test sample.Thermal shock chambers are designed for quick transitions between Cold and Hot temperature zones. These chambers are available in vertical and horizontal configurations, with two or three zones. The difference lies in the test method and internal construction.

The two-zone cold and hot thermal shock test is divided into a high-temperature zone and a low-temperature zone.

The three-zone cold and hot thermal shock test is divided into a high temperature zones, a low temperature zones and a test area.

4.Sample weight

The weight of the test piece is also a very important parameter, as large volumes can adversely affect test performance: the performance of the climatic chambers, such as the temperature slope, calculated and specified with empty chamber, i.e. without any mass inside the test chamber. Therefore, when the required value of the required temperature exchange rate for the test piece is close to the value of the temperature exchange rate given in the technical data sheet (with empty chamber), it is necessary to carry out a home inspection. supply room.

Weight is a parameter that must be taken into account for another reason: the test cabinet racks are designed to support specimens up to a certain weight. Therefore, it is best to check the rating plate for what the maximum weight of the test piece is.If the test piece exceeds the maximum permissible weight, the cabinet accessories include a reinforced bracket or bracket.

5.Performance of the sample to be tested

A. The sample operates normally during testing:When the test piece is connected to a power source (active sample), it may dissipate heat. In some cases this may be irrelevant, but in others it should be taken into account as it may affect the performance of the test box, which is usually empty, i.e. without volume and heat dissipation, as described above. Therefore, when the test piece is operated, the test chamber should carry away the heat emitted by the test piece without affecting its performance, in which case the test values are in accordance with the requirements.

B. Special cases: In some special cases, the heat dissipation of the test chamber may also be affected.In some special cases, test pieces may emit flammable, explosive, toxic and/or corrosive substances or substances that may produce potentially hazardous gases, depending on the temperature range they can reach. In such cases, customers need to consult RIUKAI to accurately assess the risks associated with the test.

1-1.jpg)