A corrosion test chamber is a controlled environment used to simulate and accelerate the corrosion process on materials, typically through exposure to conditions such as salt spray, humidity, or temperature fluctuations. These chambers help in assessing the corrosion resistance of coatings, paints, and metals, ensuring products meet quality standards in real-world conditions.

How do You Test for Corrosion?

Testing for corrosion is done using several methods, depending on the material and the desired outcome. The salt spray test is one of the most common, where specimens are exposed to a saline mist for an extended period. Other tests include humidity testing, where materials face fluctuating moisture levels, and temperature cycling, which exposes products to extreme temperatures to observe degradation.

Types of Corrosion Testing

There are various types of corrosion tests to assess material durability:

- Salt Spray Testing simulates a marine environment and is widely used for coatings.

- Cyclic Corrosion Testing combines different environmental conditions to mimic real-world scenarios.

- Electrochemical Testing provides insights into the corrosion rate and behavior of materials.

Which Corrosion is Difficult to Detect?

Pitting corrosion is particularly difficult to detect. It occurs in small, localized areas on the surface of metals, often without noticeable signs until significant damage has been done. This type of corrosion is especially problematic for stainless steel and other alloys in environments where chloride ions are present.

What Equipment is Used in Corrosion Testing?

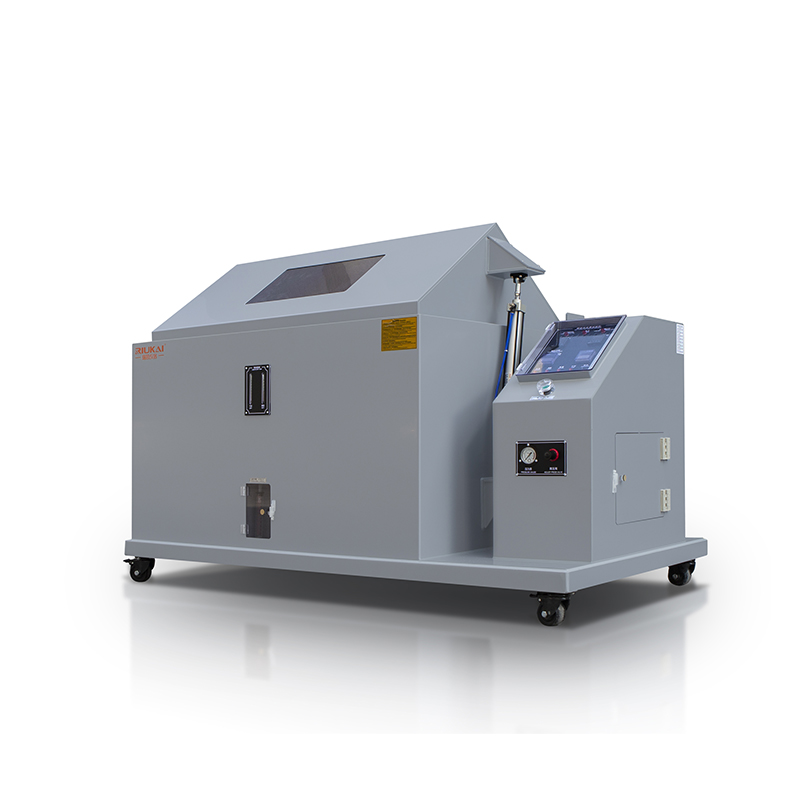

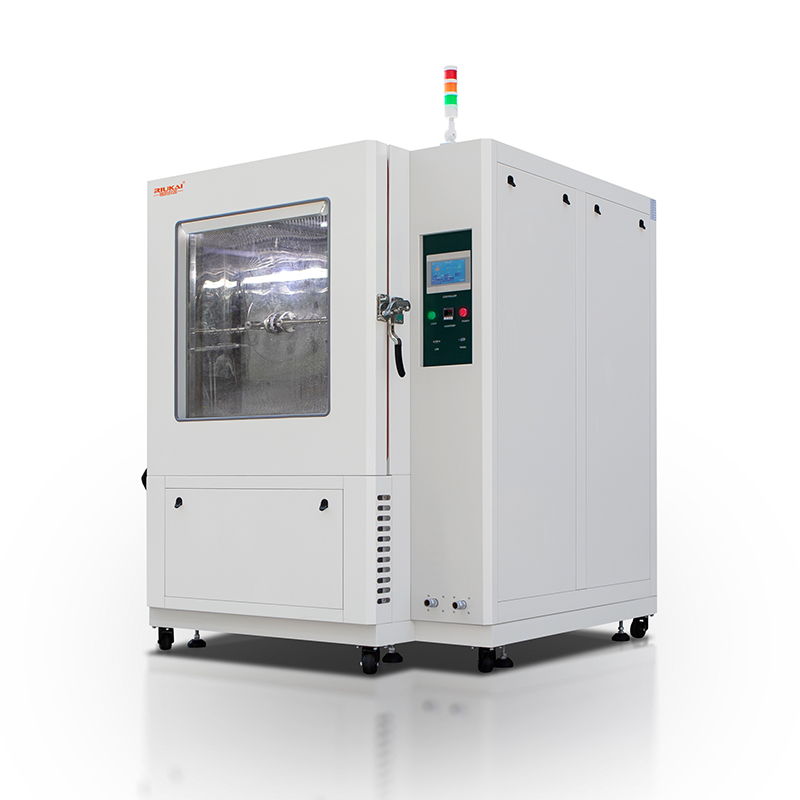

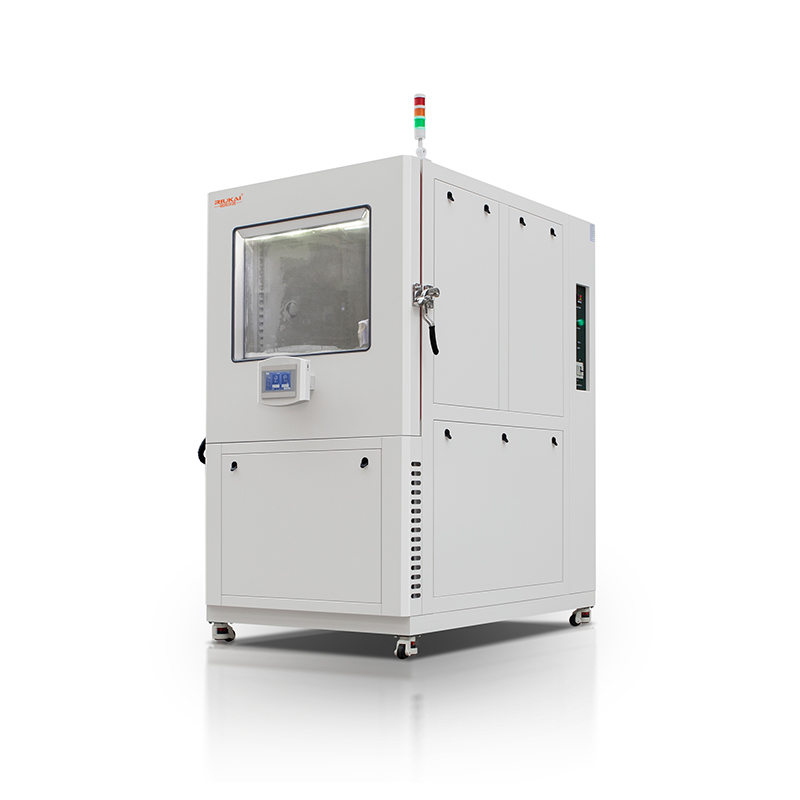

Corrosion test chambers come in various configurations, depending on the testing needs. Common types include salt spray chambers, cyclic corrosion chambers, and humidity chambers. These are equipped with systems to precisely control factors like temperature, humidity, and salinity, ensuring consistent and repeatable results.

Summary of Corrosion Test Chambers

RIUKAI provides salt corrosion test chambers with intelligent control, temperature and corrosion-resistant chambers, rapid temperature control and highly accurate spray system, applicable to a variety of materials and their protective layer of salt spray corrosion test, to ensure the accuracy and reliability of the test results.