Corrosion can compromise structural integrity and reduce the lifespan of materials. Without proper testing, products may fail prematurely, leading to costly repairs. A Salt Spray Test can prevent this by evaluating corrosion resistance.

The Salt Spray Test evaluates a material’s resistance to corrosion by exposing it to a salt-laden mist in a controlled environment. It helps ensure durability and reliability for various applications.

Understanding corrosion and the importance of the Salt Spray Test can save time, money, and resources. Let’s delve deeper into this essential testing method.

What is Corrosion?

Corrosion is the gradual deterioration of materials, often metals, caused by chemical or electrochemical reactions with their environment. Common types include rusting, pitting, and galvanic corrosion. Environmental factors like moisture, temperature, and salinity accelerate the process. Left unchecked, corrosion can lead to equipment failure, safety risks, and financial losses.

What is a Salt Spray Test?

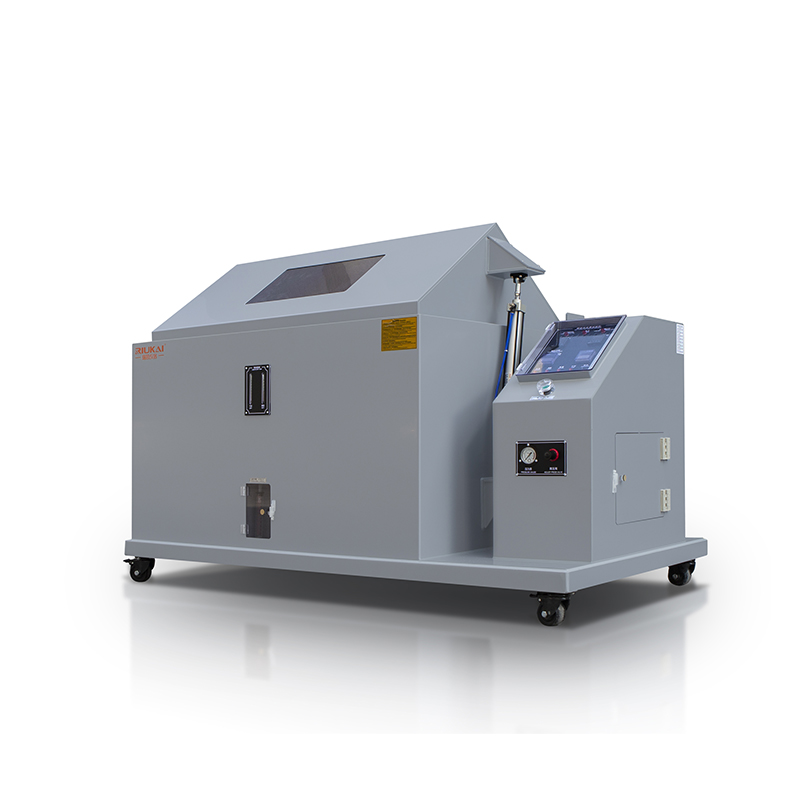

The Salt Spray Test is an accelerated corrosion testing method. It involves placing materials in a chamber where they are continuously exposed to a fine mist of salt solution. This controlled environment simulates harsh conditions to evaluate a material’s resistance to corrosion. The test is widely used in industries like automotive, aerospace, and construction to assess coating durability and material performance.

Purpose of the Salt Spray Test

The primary purpose of the Salt Spray Test is to predict how materials will withstand real-world conditions. It identifies vulnerabilities in protective coatings, helps refine product designs, and ensures compliance with industry standards. By simulating years of environmental exposure in just days, the test provides invaluable insights into material longevity and performance under stress.

Salt Spray Test Standards

The Salt Spray Test adheres to internationally recognized standards, ensuring consistency and reliability in results. Key standards include:

- ASTM B117: The most commonly used standard for conducting Salt Spray Tests.

- ISO 9227: A global standard for salt spray testing in different industries.

- JIS Z 2371: A Japanese standard often employed in automotive and electronics sectors.

These standards specify parameters like solution concentration, temperature, and exposure duration, ensuring uniformity in testing across industries.

Limitations and Considerations

While the Salt Spray Test is effective, it has limitations. It primarily evaluates the initial resistance of materials rather than long-term performance. The test does not account for factors like mechanical stress, UV exposure, or environmental cycling. Manufacturers should complement it with other testing methods, such as cyclic corrosion testing, for comprehensive material evaluation.

Conclusion

The Salt Spray Test is a critical tool for assessing corrosion resistance. Proper testing ensures durable, reliable materials and saves time, money, and resources in the long run.Welcome to consult for Catalog and Product. you can contact us at email export@riukai.com.

1-1.jpg)