What Is a Pressure Test Chamber and Why Choose RIUKAI?

At RIUKAI, we specialize in designing and manufacturing Pressure Test Chambers and other environmental testing equipment. With over 25 years of experience and ISO certifications, we stand as pioneers in this industry. Our test chambers, including Altitude Chambers, Hypobaric Chambers, Highly Accelerated Stress Test (HAST) Chambers, and Pressure Cooker Aging Test Chambers, offer state-of-the-art features. Our products are recognized globally, with technical support and fast response times, ensuring reliability and excellent service.

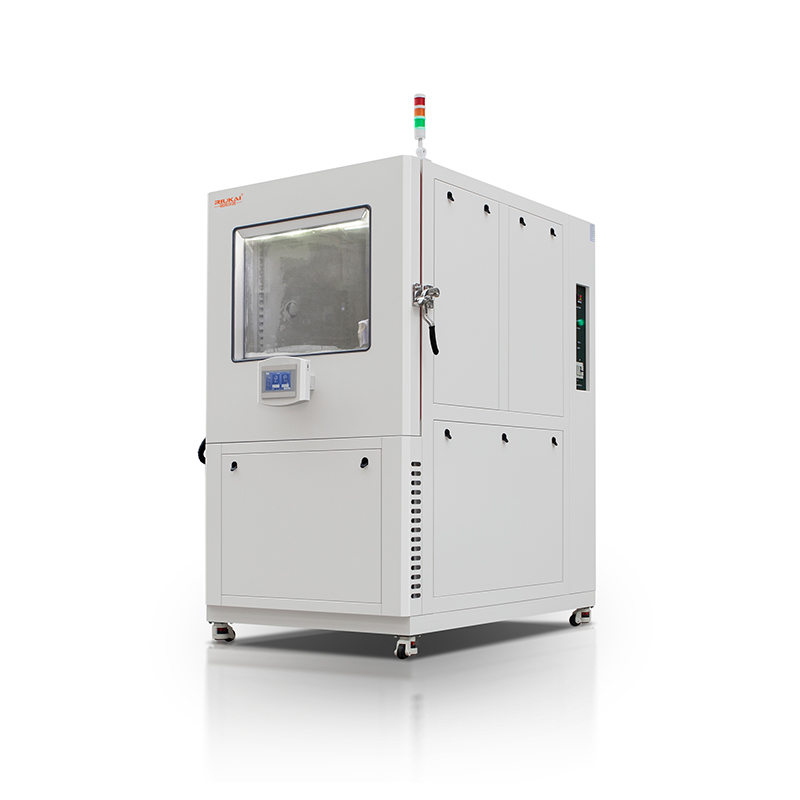

What Are Altitude Chambers and Hypobaric Chambers?

Altitude Chambers and Hypobaric Chambers simulate high-altitude conditions by creating low-pressure environments. These chambers are essential for testing products used in aerospace, automotive, and electronics industries, ensuring they can withstand low-pressure conditions. They help evaluate performance at various altitudes by simulating conditions up to 30,000 meters above sea level.

Altitude and hypobaric chambers simulate high-altitude conditions for aerospace and electronics industries, ensuring products withstand low-pressure environments for optimal performance.

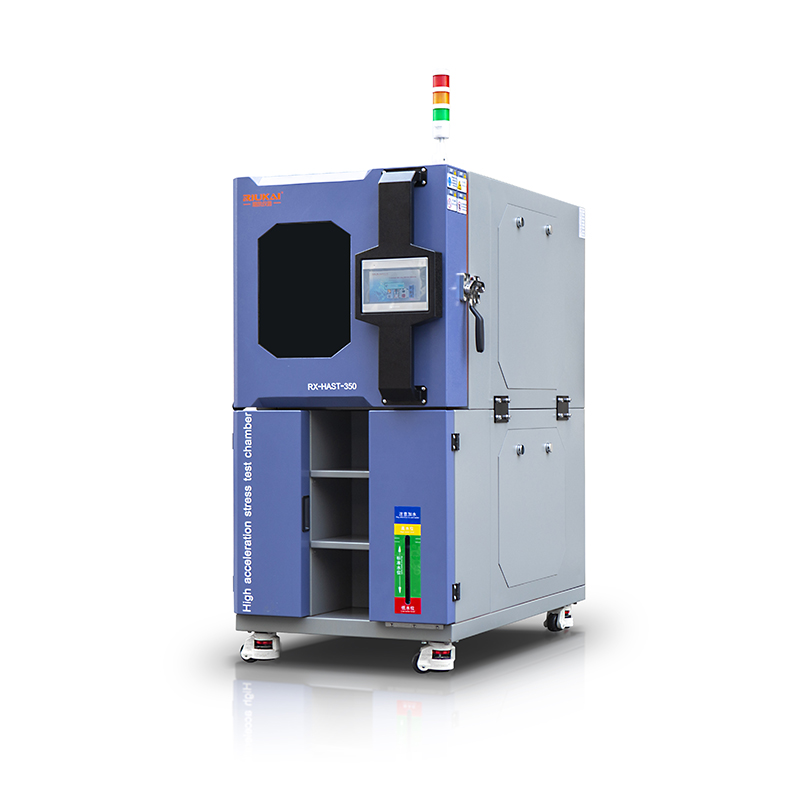

What Is a Highly Accelerated Stress Test (HAST) Chamber?

HAST Chambers accelerate stress testing by applying high pressure, temperature, and humidity to electronic components, ensuring they can withstand extreme conditions. These chambers are vital for industries where moisture resistance and long-term reliability are critical, such as semiconductors.

What Is a PCT Pressure Cooker Aging Test Chamber?

The PCT Pressure Cooker Aging Test Chamber accelerates product aging by simulating high-pressure, high-humidity conditions. These chambers are commonly used for testing electronics, polymers, and other materials to ensure durability and longevity under extreme conditions.

Transition: Keep Reading to Discover the Purpose and Functionality of Pressure Test Chambers

Now that you have a glimpse of various specialized chambers, let’s dive deeper into the purpose and functionality of Pressure Test Chambers and how they can enhance the reliability of your products.

What Is the Purpose of the Pressure Test Chamber?

A Pressure Test Chamber is used to simulate extreme environmental conditions, testing how materials or products perform under varying levels of pressure. Its purpose is to determine the durability, safety, and performance of products like electronics, automotive parts, and other critical components. By simulating high and low-pressure environments, manufacturers can identify potential product failures and improve design reliability before products reach the market.

What Is the Purpose of the Pressure Test?

A Pressure Test measures the ability of a product to withstand pressures beyond normal operational levels. This is especially important for industries like aerospace, automotive, and electronics, where materials are often exposed to extreme conditions. Pressure testing can identify weak points in a design, ensuring that a product can perform reliably under stress, thereby reducing the risk of failure during real-world use.

How Does Chamber Pressure Work?

Chamber pressure works by using compressors and valves to control the amount of pressure applied to the test environment. The test chamber can simulate both high and low-pressure conditions by adjusting the air inside the chamber. These pressure fluctuations help evaluate how the product performs in different atmospheric conditions, identifying how it might respond to stress or strain over time. By accurately controlling and monitoring pressure, manufacturers can gain insights into product weaknesses and ensure long-term reliability.

Summary Of Pressure Test Chamber

A Pressure Test Chamber is an essential tool for testing product durability under extreme conditions. With RIUKAI’s advanced chambers, you ensure product safety, reliability, and long-term performance.