RIUKAI TECHNOLOGY has 25+ years of experience in the field of environmental test chambers to meet the needs of our customers.

Environmental Test Chambers

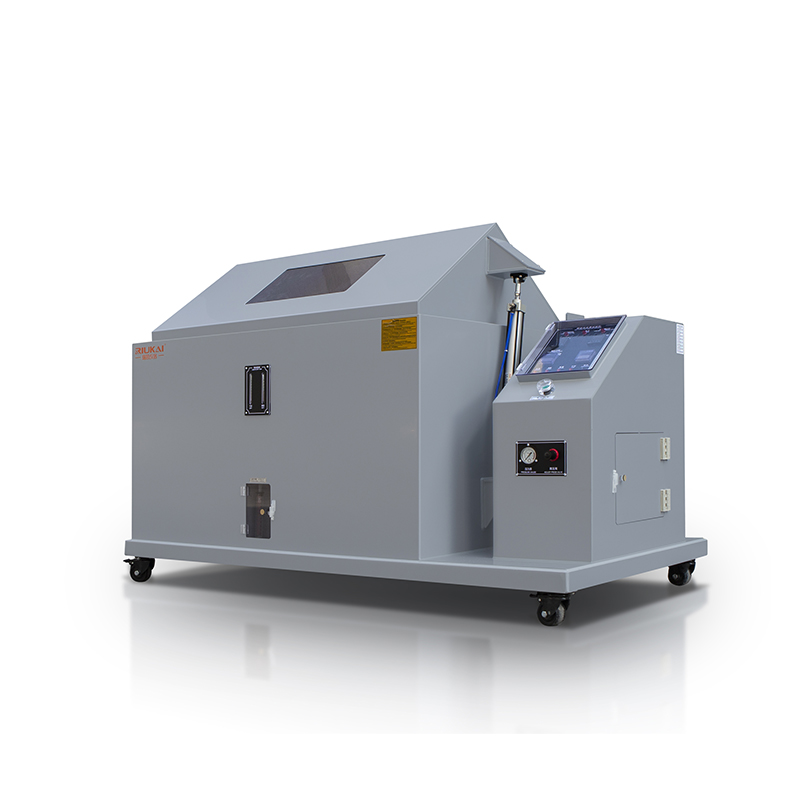

Reliable Manufacturer Of Environmental Test Chambers – RIUKAI

The environmental test chambers, often referred to as the temperature test chambers,(temperature chamber or humidity chamber)is designed to replicate a variety of temperature and humidity conditions for testing the durability and reliability of products under extreme temperatures, both high and low, as well as under varying humidity levels.

Environmental Test Chambers are suitable for quality testing of vehicles, plastic products, metals, food, chemicals, building materials, electronics, electrical appliances, mobile phones, communications, instrumentation, medical and aerospace products.RIUKAI’s reliability environmental test chambers help businesses accelerate product development, reduce costs, minimize failures, ensure compliance, and enhance product quality by accurately simulating real-world conditions and detecting potential issues early.

RIUKAI has been in the environmental test chambers industry for more than 25+ years, and as a leading supplier of temperature and humidity test chambers, we can meet a wide range of customers’ testing needs.The different industry has different requirement of temperature humidity range and temperature cycling speed. We have unique innovation capabilities worldwide and are in a leading position in the industry. RIUKAI is committed to providing global customers with a comprehensive environmental test chamber.

Other model options for Environmental Test Chambers

Environmental Test Chambers for sale

Main Functions of Humidity Chamber:

Humidity chamber, also known as constant temperature and humidity test chambers, are designed to simulate specific environmental conditions to test the reliability and performance of products and materials. Here are some key functions and features of humidity chambers:

-

-

- Temperature Control: Precisely regulates and maintains the preset temperature, ensuring stable testing conditions.

- Humidity Control: Adjusts and maintains specific humidity levels to simulate various environmental humidity conditions.

- Automatic Stop and Alarm: Automatically stops heating or cooling once the set values are reached, and provides fault alarms.

- Data Transmission and Recording: Real-time output and recording of temperature and humidity data for monitoring and analysis.

- Remote Monitoring and Control: Allows remote operation through communication interfaces, enhancing flexibility.

- Safety Protection Features: Includes over-temperature and over-humidity protection to ensure the safety of the equipment and samples.

-

These functions make the temperature and humidity chamber an essential tool for testing the performance and reliability of products and materials under different environmental conditions.

Temperature Chambers Test Standards

- IEC 68-2-1 test A: cold

- IEC68-2-14 Test method N: Temperature change

- GJB150.9-1986 military equipment environmental humidity and heat test

- GB/T 10592-1989 High and low temperature test Technical conditions.

- GB24231-1989 basic environmental low temperature test for electrical and electronic products

- GB/T 10589-1989 Low temperature test chamber Technical conditions

- GB/T 10586-1989 Humid heat test chamber technical conditions

- GB/T2423.4-1993 Electrical and electronic products test Db: alternating heat and humidity test

Category

Other Products

Frequently Asked Question

A:RIUKAI has 25 years of experience in the industry. We can undertake the manufacturing and ODM cooperation of various large-scale non-standard environmental test equipment and provide environmental reliability test solutions.

A:Payment shall be made y T/T, L/C, or D/P, etc. We can communicate and negotiate.

A:Each machine will be debugged before shipment and shipped after debugging is completed. We will provide very specific operation manual and operation video, and also provide online remote video conference to guide the operation. We can provide on-site installation and training services abroad if customers require.

A:Generally, it takes about 20-30 days, and if we have it in stock, we can arrange delivery within 7 days. Please note that our production lead time depends on the number of items.

A: We provide various types of trade terms, such as EXW, CIF, DDU, DDP, etc.

1-1.jpg)