RIUKAI’s environmental test chambers play a vital role in a wide range of industries by simulating different environmental conditions and testing the performance and durability of products. When choosing the right environmental chamber for your specific needs, it is important to understand the different types of chambers and their capabilities. This article will introduce the various types of environmental test chambers that RIUKAI can manufacture and supply.

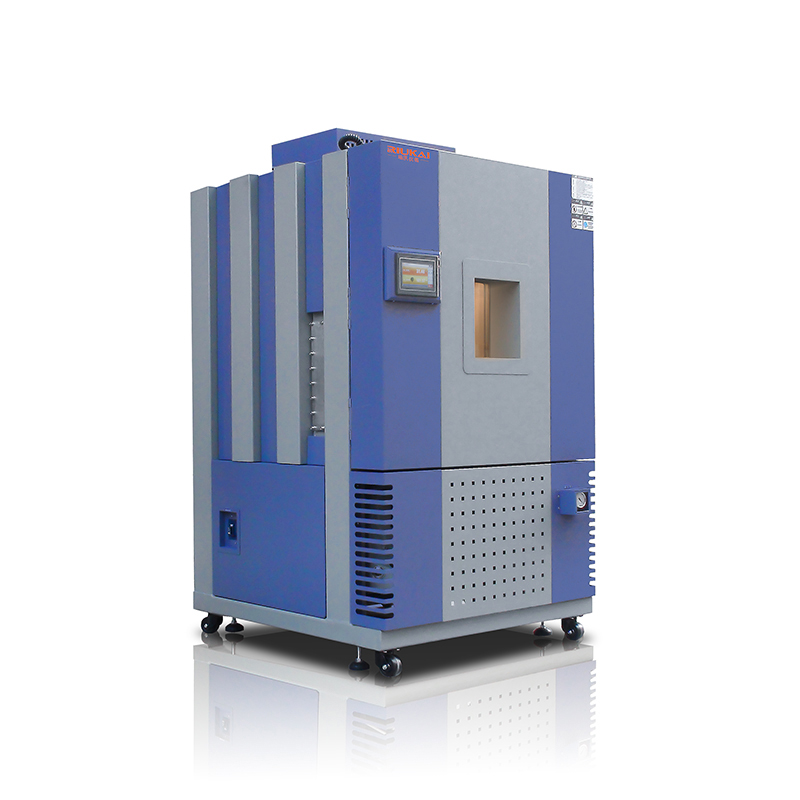

Temperature Chambers

RIUKAI’s temperature chambers are used to evaluate the performance of products under different temperature conditions. We offer temperature chambers that simulate both high and low temperatures. Enabling manufacturers, factories, laboratories to evaluate the effects of temperature changes on their products.

Humidity Chamber

RIUKAI’s humidity chambers are essential for evaluating product performance under different humidity conditions. These environmental test chambers can replicate different humidity conditions. Enabling manufacturers, factories, laboratories to determine how their products withstand humidity and humidity related challenges.

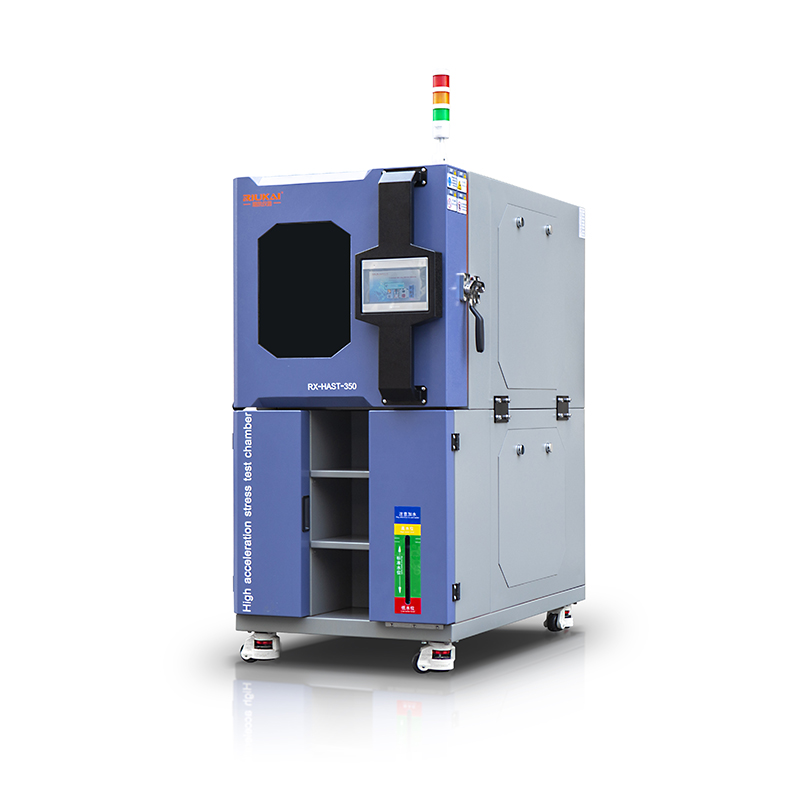

Highly Accelerated Stress Test HAST Chambers

RIUKAI Highly Accelerated Stress Test HAST Chambers combine multiple environmental factors, such as temperature, humidity, vibration, and more, to replicate real-world conditions. As truly versatile combined test chambers, they allow manufacturers to perform comprehensive testing, saving time and resources.

Altitude Test Chambers

RIUKAI Altitude test chambers are used to assess the performance of products at different altitudes. These environmental test chambers create low-pressure environments, simulating high-altitude conditions, to test how products function under reduced atmospheric pressure.

Thermal Shock Chambers

RIUKAI’s Thermal Shock Chambers are designed to evaluate a product’s ability to withstand rapid temperature changes. These thermal shock chambers expose products to alternating high and low temperatures to simulate realistic conditions and identify potential weaknesses or failures. This enables manufacturers, factories and laboratories to evaluate the effects of temperature changes on products.solution to evaluate the durability of materials and coatings.

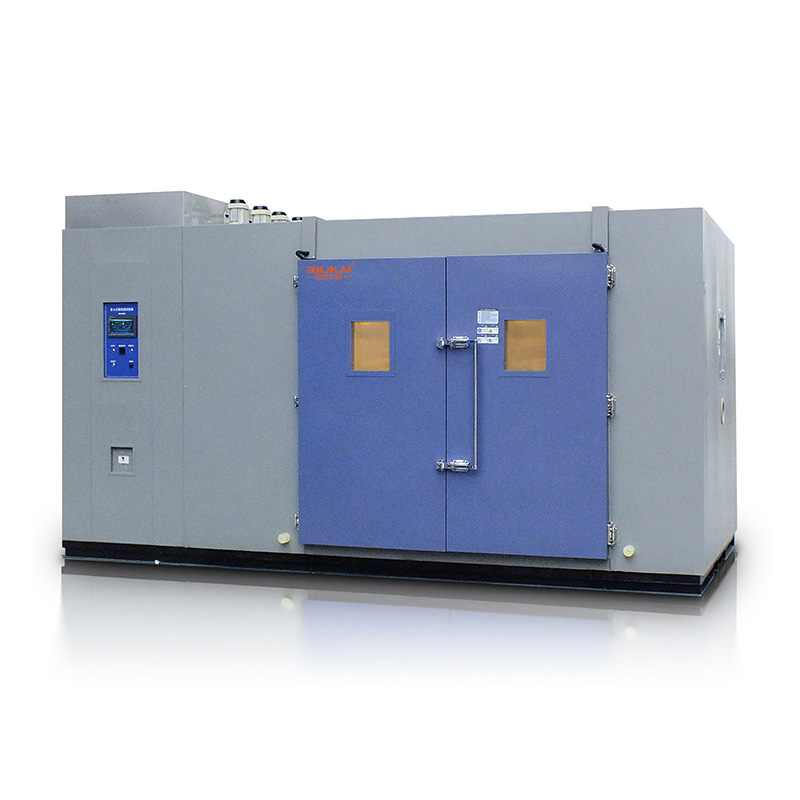

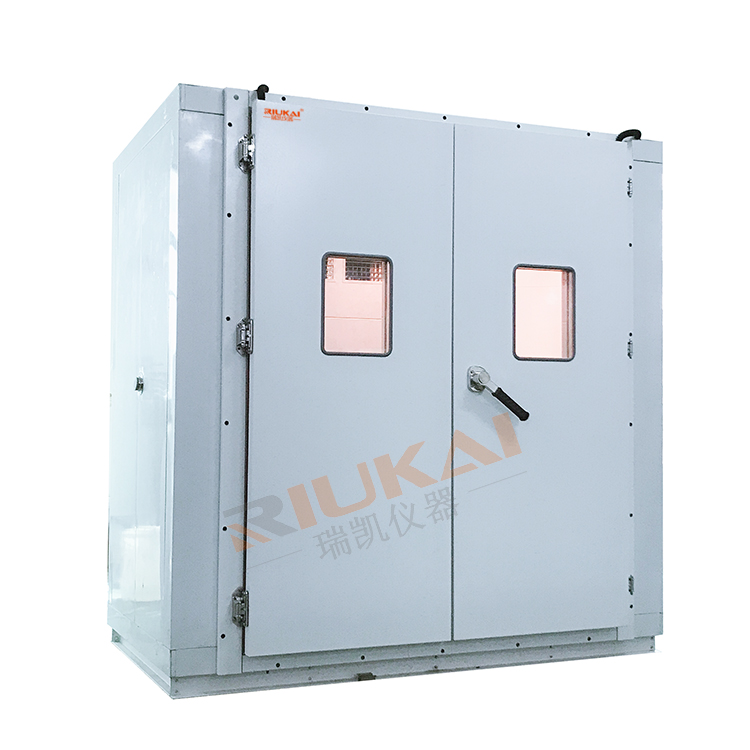

Walk-In & Drive-In Chambers

RIUKAI designs and assembles a wide range of Walk-In & Drive-In Chambers. They can be customised according to volume and shape, performance, air quality (if people are staying in the chamber), etc. The construction modes include monolithic welded floors, prefabricated modular panel structures and compact walk-in chambers.Environmental test chambers, like these, provide ample space and customizable configurations to meet specific testing requirements.

Industrial Drying Ovens/Ovens

Heating is an important part of many standard procedures for testing, and our complete portfolio of heating and drying ovens provides you with advanced user and product safety features.RIUKAI’s Industrial Dryer/Ovens are here to help. These environmental test chambers are designed to test the limits of a product or component under varying degrees of heating and drying conditions.

Dust Test Chambers

RIUKAI Dust Test Chambers provide an environment for testing automotive and electronic components exposed to high concentrations of dust to verify the integrity of product seals.This provides accurate and reliable testing environments for all your needs.

Rain Test Chambers

RIUKAI Rain Test Chambers simulate rain and other forms of water exposure and are capable of meeting water testing standards required by lEC 60598 and 60529 for lamps, automobiles and electronics, providing controlled water spray or rain-like conditions to assess the water resistance and durability of products.

Salt Spray Test Chambers

RIUKAI Salt spray test chambers are specifically used for corrosion testing. These chambers simulate salt-laden environments to assess the corrosion resistance of products. Salt spray environmental test chambers provide a controlled environment with a saline