Environmental testing is crucial for ensuring products can withstand a range of real-world conditions. But can one testing chamber handle multiple conditions at once? Let’s explore the possibilities.

A single environmental testing chamber can simulate multiple conditions simultaneously with the right technology. This allows for more efficient testing without the need for multiple chambers.

Keep reading to discover how multi-condition chambers work and why they’re an invaluable tool for product testing.

What Types of Environmental Testing Services Are Available?

Environmental testing services include a wide range of tests designed to simulate various environmental conditions such as temperature, humidity, altitude, and vibration. Some common types of environmental testing services include:

- Thermal Shock Testing: This test involves exposing a product to extreme temperature fluctuations to simulate conditions such as rapid climate changes.

- Humidity Testing: Testing how a product performs in high or low humidity conditions, which is critical for items exposed to wet or dry climates.

- Vibration Testing: Simulates the shaking or motion products experience during transportation or operation, ensuring durability under such conditions.

- Corrosion Testing: Used to assess how products fare when exposed to salt, moisture, and other corrosive elements over time.

- Altitude Testing: Exposes products to lower air pressures to replicate high-altitude conditions or transportation by air.

These services allow companies to understand how their products will perform under various environmental factors, ensuring better reliability and safety.

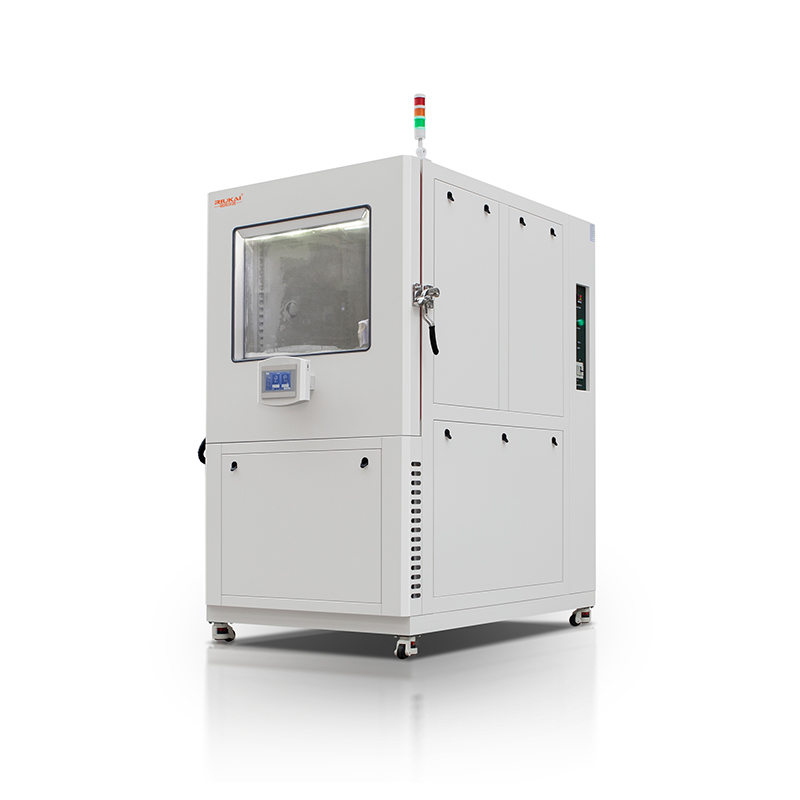

Features of Multi-Condition Environmental Chambers

Multi-condition environmental chambers are equipped with advanced technologies that allow them to simulate a variety of environmental conditions at once. The main features include:

- Independent Control Zones: These chambers have multiple zones, each with its own independent controls for temperature, humidity, or pressure. This allows different sections of the chamber to simulate different environmental conditions simultaneously.

- Precise Environmental Control: Advanced sensors and control systems ensure that temperature, humidity, and other environmental factors are maintained with high accuracy, even in multi-condition settings.

- Versatility: These chambers can simulate complex conditions like high humidity at low temperatures, or high-altitude conditions combined with extreme temperatures. This is crucial for testing products designed to perform in diverse environments.

- Real-Time Data Logging: Data from each test is logged and monitored, giving precise insights into how products react under various simulated conditions. This data is invaluable for product development and quality assurance.

- Customizable Test Profiles: Many multi-condition chambers offer the ability to create customizable testing profiles, which means users can configure the chamber to simulate exactly the environmental conditions required for their specific product.

With these features, multi-condition chambers help reduce the need for multiple machines, saving both time and cost while increasing testing flexibility.

Why is Environmental Testing Important?

Environmental testing is essential for determining how products behave under extreme conditions. This helps ensure that they will perform reliably in real-world situations. Here are several reasons why environmental testing is crucial:

- Product Durability: Testing helps determine the durability of products in various environments, ensuring they can withstand exposure to different weather conditions, humidity levels, and other factors.

- Safety and Compliance: Environmental testing is vital for meeting industry safety standards and regulatory requirements. Products that are intended for use in harsh environments (such as aerospace, automotive, or military industries) must pass environmental testing to ensure they are safe and reliable.

- Quality Assurance: Regular testing ensures products meet the necessary quality standards and function as expected. This is particularly important in industries where failure could result in catastrophic consequences.

- Cost-Effective Product Development: By identifying potential issues early in the design process, environmental testing helps reduce the cost of recalls, repairs, or product failures later on. Testing multiple conditions simultaneously makes the process even more efficient.

- Market Readiness: Comprehensive environmental testing ensures that a product is ready for the global market. Whether it’s for high-altitude regions, extreme temperatures, or coastal areas with high humidity, testing ensures the product can handle the diverse conditions it will face.

Conclusion

Multi-condition environmental chambers are a game-changer for testing efficiency, allowing for the simulation of multiple environmental conditions at once. These chambers are vital tools for ensuring product reliability, safety, and performance across various conditions.

1-1.jpg)