Corrosion Test Chamber: How Can It Protect Your Products?

Problem: Corrosion leads to expensive product failures and safety risks. Ignoring corrosion can result in costly repairs, downtime, and potentially dangerous situations.

Solution: A Corrosion Test Chamber simulates corrosive environments, helping you identify vulnerabilities before they escalate.

Your products’ durability depends on understanding how they withstand corrosion. Conducting corrosion tests ensures product reliability and helps you avoid future failures.

How Many Types of Corrosion Tests Are There?

Corrosion testing includes a range of methods to simulate real-world conditions:

- Salt Spray Test – For assessing corrosion resistance in marine and industrial environments.

- Cyclic Corrosion Testing – Alternates between wet and dry cycles to simulate natural environmental changes.

- Humidity Testing – Examines how materials hold up in humid conditions, which can accelerate corrosion.

- Electrochemical Testing – Measures corrosion rates by monitoring electrical currents in a simulated corrosive environment.

Each test provides insights into different aspects of a material’s corrosion resistance, offering manufacturers comprehensive data to improve their products.

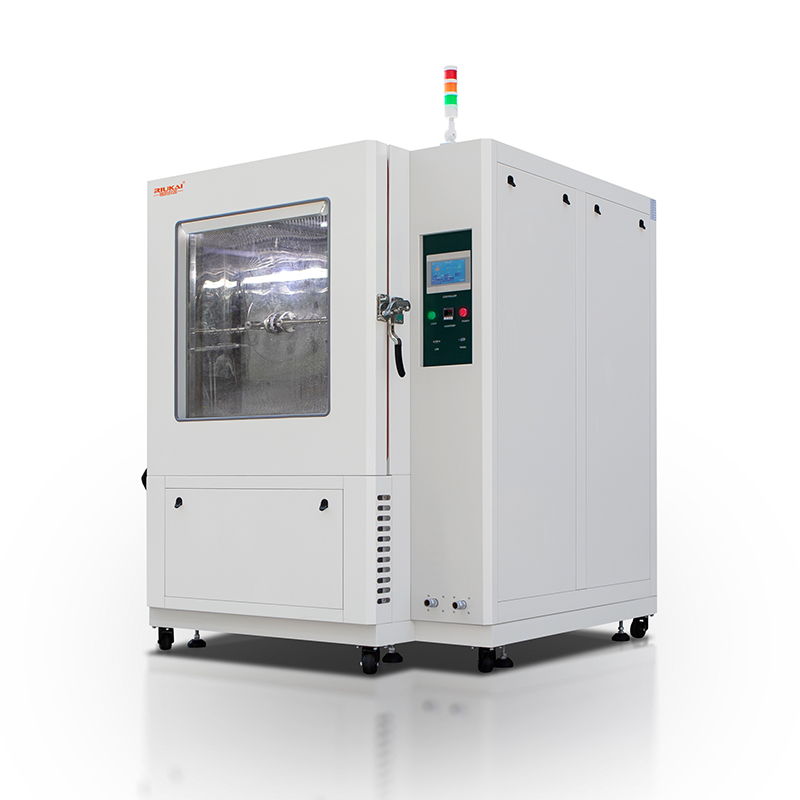

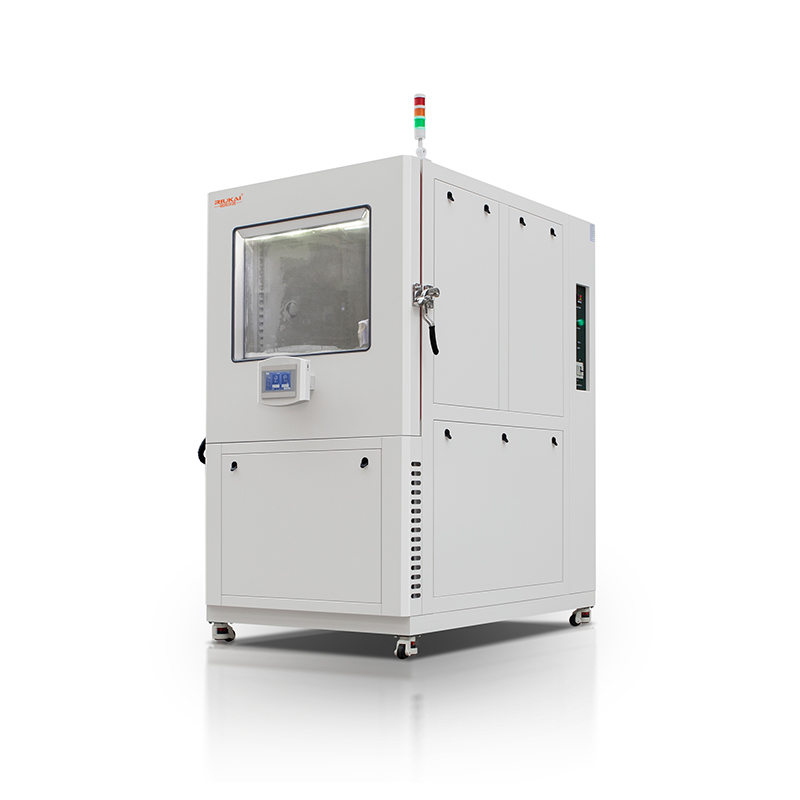

What is a Corrosion Test Chamber?

A Corrosion Test Chamber is a specialized device that simulates harsh environmental conditions like salt spray, high humidity, or temperature fluctuations. It allows manufacturers to replicate real-world corrosive scenarios to assess the durability and longevity of their products. Chambers can be customized for various tests, including salt fog, humidity, and cyclic corrosion. Modern chambers also offer precise control of temperature, humidity, and airflow to ensure consistent test results.

How Do You Test for Corrosion?

Testing for corrosion involves placing materials in a Corrosion Test Chamber where they are subjected to corrosive elements like salt spray, humidity, and fluctuating temperatures. The chamber runs for specific durations, allowing manufacturers to observe how materials degrade over time. After testing, products are examined for surface damage, pitting, rust, and structural weaknesses. These results help predict how materials will perform in real-life environments, guiding product improvements.

Why RIUKAI as your Salt Spray Chamber Manufacturers?

RIUAKI is a brand of environmental test chambers with over 25+ years of experience. We are able to produce salt spray test chambers that meet the needs of different industries for testing the corrosion resistance of materials and products. Choosing the right salt spray test chamber manufacturer is critical to ensuring the quality and reliability of your products in corrosive environments.By using a corrosion test chamber, you can ensure that your products meet industry standards and can withstand the toughest environmental challenges.Contact RIUKAI for more information on salt spray test chambers.

1-1.jpg)